10" x 40, Laser Thin Kerf Saw Blade

The Exclusive Infinity Cutting Tools Laser Thin-Kerf blade removes a sliver-thin amount of material (1/16") and makes quick work of ripping and crosscutting in hardwood, softwood, composites and plastics. At half the thickness of a standard-kerf blade, the 10" x 40 Tooth Laser Kerf requires less power, cuts cleaner and leaves a super-smooth finish.

I was skeptical at first. Why would anyone need a blade so thin that it only cuts a 1/16" kerf? Then I tried the Laser Thin-Kerf Table Saw Blade (010-046) by Infinity Cutting Tools. Not to sound too cliché, but it cut like a hot knife through butter. Seriously. It sliced through 2"-thick red oak, 3/4" mahogany, and 3/4" cabinet-grade birch plywood without flinching. And the resulting cut edge was flawless. Best of all, there was minimal, if any tearout. This is impressive, especially when cutting plywood. (A zero-clearance insert also helps immensely, regardless of the blade you're using on your table saw.)

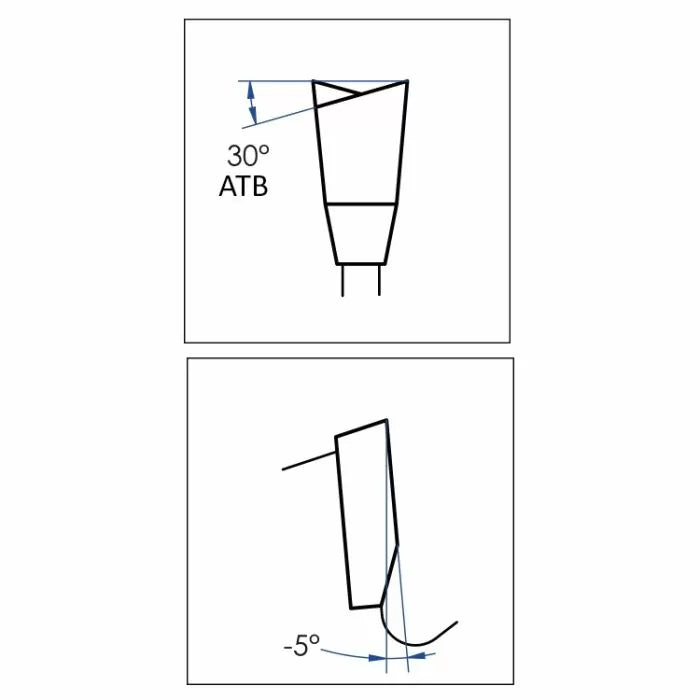

So, the Laser Thin-Kerf table saw blade makes a great all-purpose blade. Next to a general-purpose combination blade, I wouldn't hesitate to keep the Laser Thin-Kerf blade on my saw. As I already mentioned, it cuts superbly, thanks to the tooth configuration. The 40-tooth, ATB (alternate top bevel) grind and negative hook angle make smooth scoring and shearing cuts.

This blade is also so much quieter to run than other blades. It doesn't scream at you, even when cutting through thick material. The Laser Thin-Kerf table saw blade features two steel stabilizer disks permanently attached to the sides of the blade. These help eliminate any vibration and also serve to dampen the noise. During the manufacturing process, the blade body is flattened for minimal runout and vibration. This is a smooth-running blade. You'll notice that the first time you fire it up.

The blade plate also features Infinity Cutting Tools exclusive Nickel Armor Coating to reduce operating friction as well as prevent the buildup of pitch and gum. It's just one of those little things that makes a big difference.

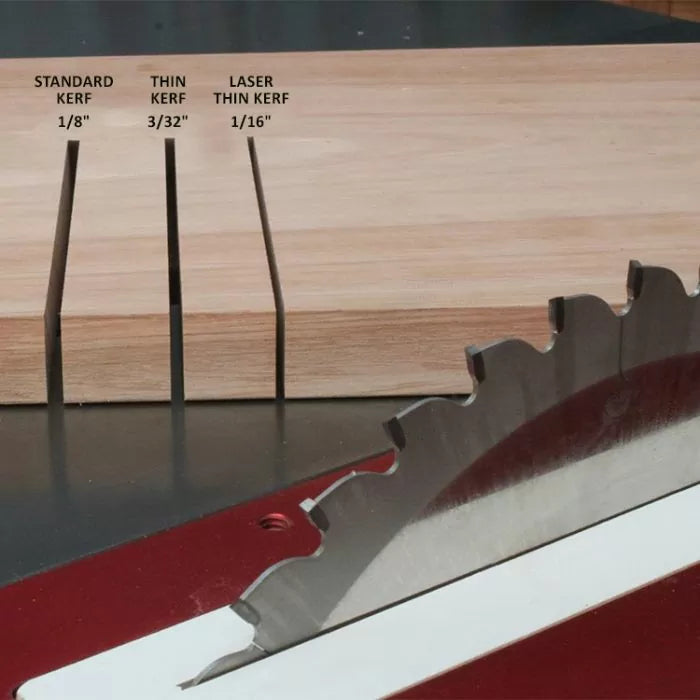

But the question still remains, why do you need a blade that cuts a kerf only 1/16" wide? There are several reasons. The obvious reason is that there's less material waste with each cut. You're leaving 50% more material than you would using a full, 1/8"-kerf table saw blade. And you're leaving 33% more material vs. a thin-kerf (3/32") table saw blade. Why does this matter? It matters when material cost is a consideration for your projects. If you want to experiment with exotic wood species, for example, you'll pay a hefty price for the material. So, savings are real when you make cuts with a Laser Thin-Kerf blade vs. a standard table saw blade.

Another advantage to using a blade with an ultra-thin kerf is that there's less stress on your table saw's motor. You're removing less material. Each tooth is taking a much smaller bite than traditional table saw blades.

The Laser Thin-Kerf Table Saw blade creates a saw kerf only 1/16"-wide (right). An 1/8" kerf (left) is made with a standard blade. The center kerf is made with a 3/32" thin-kerf blade.

There's one other thing I need to mention. The Laser Thin-Kerf table saw blade also excels at ripping workpieces to width. But you won't be able to use your stock riving knife or splitter. First of all, the blade is thinner than most splitters and riving knives. Secondly, the stabilizers on the sides of the blade offset the blade body from its normal position next to the flange on your saw's arbor. This means the teeth may not line up with your riving knife or splitter. To solve these problems, we recommend using our Splitter For Laser Thin-Kerf Saw Blade. It's a simple steel splitter that easily attaches to your saw's insert plate with a pair of screws. The included instructions make it an easy installation.

All in all, the Laser Thin-Kerf table saw blade by Infinity Cutting Tools is a worthwhile investment and one you'll appreciate making the first time you use it.