Laser Thin Kerf

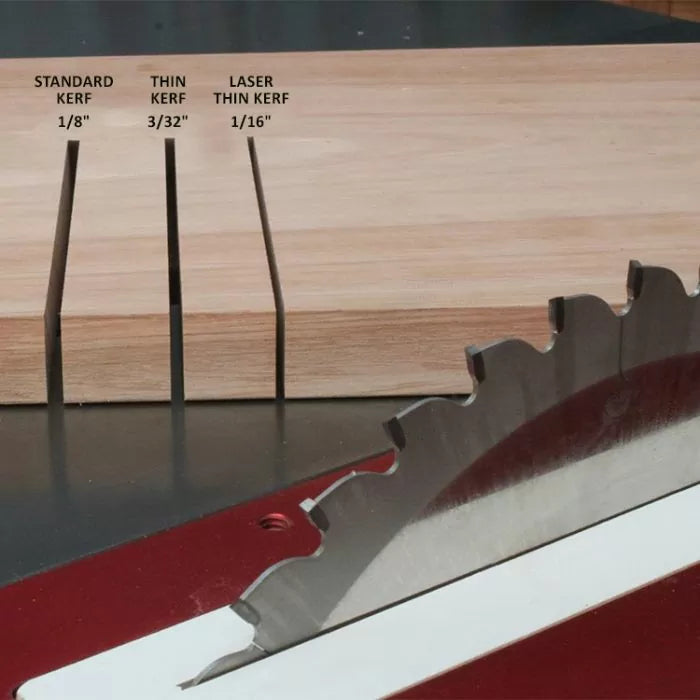

It’s rare that something new hits the woodworking market, but this Laser Thin Kerf table saw blade is truly unique. With a staggeringly narrow blade kerf of just 1/16”, it’s the thinnest kerf blade available. There’s less waste and less sawdust produced by this laser-thin kerf. In fact, it’s half the width of a traditional 1/8” full kerf woodworking blade.

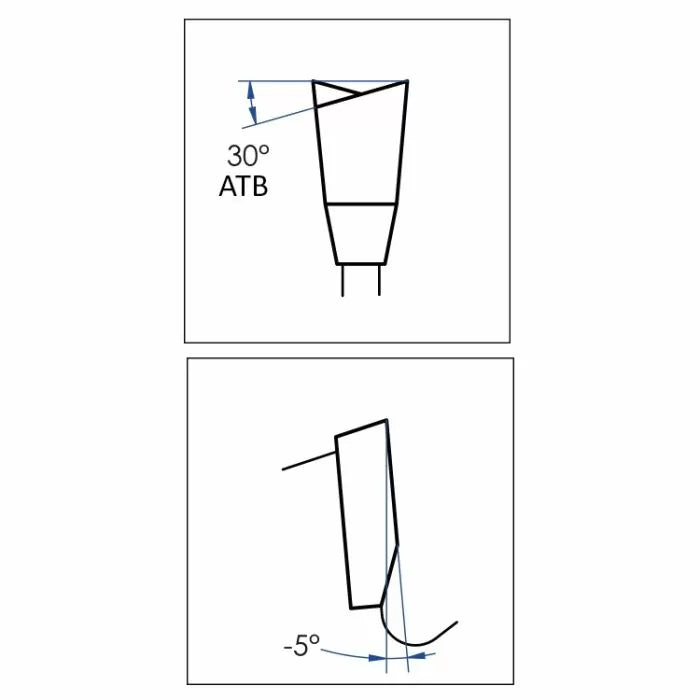

Blade Geometry

By design, this table saw blade is a great performer for both ripping and crosscutting hardwood, plywood and delicate veneers. With 40 high ATB micro-grain C4 carbide teeth, it’s perfectly situated to handle cuts both with and against the grain. Beyond that, a negative hook angle makes this a smooth performer, with virtually splinter-free cuts.

How is This Possible?

The laser thin kerf is possible thanks to a pair of precision machined stabilizers, permanently attached to the body of the table saw blade with five copper core rivets. These blade stabilizers flank the body of the blade, allowing such an incredibly thin kerf. While this does limit the overall depth of cut to 2", you’ll find the reduced waste and effortless cutting are a worthwhile compromise.

Whisper Quiet Operation

The extra mass of the blade stabilizers absorb vibration, along with decreased friction from the Chrome Armor coating make this a whisper-quiet blade in the shop.

Laser-Thin Splitter Available

Offered alongside the Laser Thin Kerf blade is a Laser-Thin splitter accessory that you can mount to a zero-clearance tablesaw throat plate for optimal performance. A zero clearance insert (ZCI) covers and protects the area around the blade, for improved cut quality and safety. If there’s any trepidation about installing a splitter, stick around to learn how.

Start with a Blank Slate

Install a blank, uncut throat plate into the opening in your saw. If you use a Sawstop, you’ll want a blank dado insert. Clamp a board across one side of the insert for safety, as you raise the spinning blade to create an initial kerf (use a board like this for safety, even if your saw uses a locking throat plate).

Clear the Obstructions

Remove any metal, such as this “bucket-handle” locking lever, that might be in the way. Also, check for set screws that might be in your planned cutting path when making a slot for the splitter.

Align & Slot it Out

Position the rip fence so the ZCI drops easily over the previous kerf you cut. From there, set the blade height just higher than your insert thickness, and make a stopped slot in the back of the ZCI. Note the slot for the splitter stops before it reaches the blade slot.

Safety First: You might notice a temporary ZCI made from MDF is installed in the saw to make this cut. Never operate a tablesaw without an insert installed.

Install the Laser Thin Splitter

Pre-drill for the screws that come with the Laser Thin Splitter. When working with phenolic, like this Sawstop ZCI, drill the holes a little larger than when working with wood. This will prevent the phenolic from cracking.

Pro Tip! A dab of paste wax lubricates the threads, and makes the screws easier to drive by hand.

Ready to Roll

Since the blade stabilizers offset the blade from the normal position, you’ll need a dedicated ZCI for this blade. While a shop-made ZCI is fine for some tasks, I prefer a lockable throat plate whenever using a splitter. That way, the insert will never lift up in regular use.

Wow, That’s Thin!

When you see the laser thin kerf next to a slot from a traditional full-kerf blade, the difference is staggering. Are we really wasting that much precious hardwood with every pass? If you’re using a full-kerf blade you are. And with repeated cuts, that waste (and sawdust!) really adds up.

Burn-Free Cutting Bliss

With the splitter installed, and a zero clearance insert to support the wood fibers, the result is a clean splinter-free rip cut. And woods that are highly susceptible to burning like cherry or maple, suddenly become easy to work. And you won’t believe the effortless feed resistance from this Laser Thin Kerf Blade! It’s truly like the blade is cutting thin air.

Handle it All

Ready to handle ripping and crosscutting in in a variety of materials? The 40 tooth Infinity Laser Thin Kerf blade handles hardwoods, softwoods, composites and plastics, not to mention delicate cabinet grade plywoods, and veneers.

You’re Looking at Your Next Favorite Blade

Less waste. Less sawdust. Effortless feeding of dense hardwood stock. The reasons to get a Laser Thin Kerf blade are plentiful.