Saw Blade University - Part 3

Saw blade selection is very much proprietary to your saw, what you cut, and your cutting objectives. The basic signs of top quality are characteristics like premium materials, precision construction and advanced design. Good fit and finish, large polished carbide tips, C.N.C. laser cut heavy steel plate, and coatings are not a guarantee of high quality but they are a strong indicator that a premium blade was the intent of the manufacturer. Some saw blades are better suited for certain applications and work best on specific types of saws. Blades for the table saw tend to have a positive hook angle while blades for a sliding compound miter saw (SCMS) and radial arm saw (RAS) tend to have a very low to negative hook angle. There are different blade designs for wood, plywood, melamine, laminates, MDF, plastics, and non-ferrous metals. Look for a blade that’s recommended for the type of saw you own and the applications that you intend to use it for. Choosing appropriate saw blades and cutters is among the most important choices you will make for the performance and safety of any tool. Infinity saw blades are designed to offer superb cuts, reliable performance and extended cutting life. We achieve this by manufacturing saw blades that only use the highest quality materials, manufacturing techniques and employ advanced design.

Saw Blade recommendations

Table Saw Blades - Table saws are used to perform both ripping and crosscutting operations. One important decision for saw owners to make is whether to choose separate task-specific blades that have excellent performance in a specific application but have limited versatility or use a general-purpose blade that will give good results in most applications. There’s merit to both philosophies depending on the situation, your preference, budget, and cutting objectives. Note that a saw blade with better performance in one aspect of cutting doesn’t necessarily mean it’s a better choice for your needs overall.

Many types of cuts, many types of blades - Using task-specific blades requires owning at least two saw blades (typically a 24T rip blade and a 60T or 80T crosscut blade) that each excel in a limited operating region, and are not ideal for tasks outside of their intended scope. It also requires blade changes for each different task to achieve optimum results. Two task-specific blades will generally stay sharp longer than a single general purpose blade because the workload is shared by more teeth. A general-purpose saw blade will neither rip as efficiently in thick material as a dedicated rip blade, nor cut as cleanly as a dedicated crosscut blade, but you may find that it’s more than acceptable at doing both tasks for most situations. However, a high-quality general purpose blade will leave a cleaner edge than the rip blade, will crosscut faster than a crosscut saw blade and will do so with the convenience and cost savings of using only one blade. A high-quality general-purpose saw blade will leave a glue-ready edge. If you happen to do a lot of specialty cutting of fine veneered plywoods, veneers, melamine, MDF, plastics, etc., or need very fine cuts, a specialty task-specific saw blade is recommended. If you tend to rip very thick dense materials regularly, then a dedicated ripping blade is a wise choice. Ultimately for table saw use, having a dedicated rip blade, a dedicated crosscut/plywood blade, and a high-quality general purpose blade will cover the vast majority of cutting needs. We have several saw blade package deals that include specialized saw blades in one money-saving package.

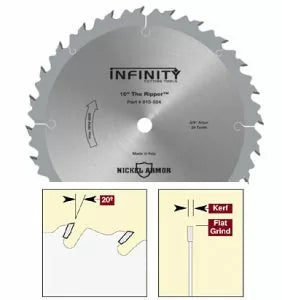

Ripping Blades - Ripping operations are cuts that go with the wood grain. They can require a lot of power from your saw, and an appropriate ripping saw blade can make a significant difference to both the saw and the quality of the cut. For efficiency, ripping blades typically have lower tooth counts than any other type of saw blade (which inherently gives them larger gullets), frequently feature FTG teeth, and have a steep positive hook angle to ease the required feed pressure of pushing a board through the blade. If your saw is less than 3hp, a good thin kerf rip blade can be advantageous. Suggestions: Infinity 010-024 or Infinity 010-124 for saws under 3hp.

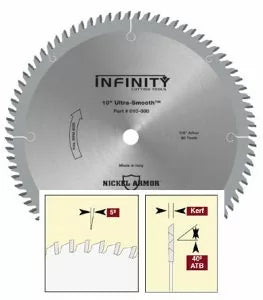

Crosscutting Blades - Crosscutting operations are cuts that go across the wood grain. Cuts across the grain are inherently more prone to tear out than cuts with the grain, so a blade with more teeth that sheers the fibers is best. Blades with 60 to 80 teeth with an ATB or Hi-ATB grind, and a moderate hook angle are best suited for crosscuts. The same characteristics are also desirable for ultra-fine plywood cuts. Suggestions: Infinity 010-180 or Infinity 010-080.

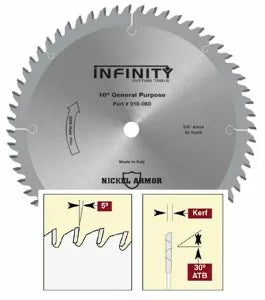

General Purpose Saw Blades - General Purpose Blades are designed to perform all table saw operations with satisfactory results. Typical general purpose blade configurations include 40T ATB blades with steep hook angles, and 50T ATB/R combination blades. Both will give smooth efficient rip cuts, and low tear out crosscuts in most situations, and are similarly versatile in plywood and sheet goods. Suggestions: Infinity 010-044 Super General, Infinity 010-050 Combomax or Infinity 010-150 Combomax Lite for saws under 3hp.

Radial Arm Saw (RAS) and Sliding Compound Saw (SCMS) Blades - The sliding action of a RAS and SCMS require a blade with a hook angle range of negative, to low positive (approximately -7° to +7°) to prevent “climb” or self feeding of the work piece. Most blades with a suitable hook angle have a medium to high tooth count, often in the 60T to 80T range. You can choose from a Hi-ATB grind for the lowest possible tearout, 010-280, or a Triple Chip grind (TCG) 010-380 for best durability. A blade with a flat top raker combined with either a Hi-ATB or ATB grind to increase durability while retaining low tearout characteristics is also a good choice, 010-280. The latter configuration is especially well suited to handle the chopping action of a compound miter saw (CMS). Suggestions: 012-190, or 010-080.

Thin-kerf vs. Full kerf blades - The kerf of the saw blade is essentially the width of the widest part of the face of carbide teeth, and equates directly to the cutting width of the blade. Saw blades fall into two kerf classifications – full kerf or thin kerf (TK), but there are exceptions. Most full kerf saw blades have wider teeth and proportionately wider body plates than thin kerf blades and are commonly in the range of 1/8” wide (~0.125”, ranging from roughly 0.111” to 0.145”), while most thin kerf blades are about 3/32” wide (0.094”, ranging from roughly 0.090” to 0.106”). Full kerf saw blades tend to be more stable than their TK counterparts due to the increased steel thickness and body mass but require more power to spin. The wider the kerf, the more power required to pass the blade through the material. There will also be a proportionately higher amount of sawdust from a full kerf blade, more wood consumed in the process, and somewhat higher noise levels. The heavier mass of a full kerf plate will handle the stresses of heat better than a TK blade, so is often a more suitable choice for high volume applications. If you’re using a saw that’s under 3hp, a TK blade will pose less resistance to your saw. A high-quality thin kerf blade with proper tensioning of the body during manufacturing will rival the cut quality and performance of a high-quality full kerf blade, and can be a very suitable choice for a home shop, smaller saws, and even in many commercial settings where wood consumption is a concern. Which width to choose depends a lot on your saw and the material being cut.

Why should you buy a top-quality saw blade?

If your saw is well made and properly designed to spin true, the end performance will be largely determined by setup and blade selection. The saw will only be as good as the saw blade that’s put on it, so choose wisely. A high quality saw blade will perform better, stay sharp longer, and is worth having sharpened many times. As always, high quality tools are a wise investment.

Click here to return to our main saw blade page

For part one of Saw Blade University please click here

For part two of Saw Blade University please click here

Please visit the Infinity Cutting Tools website to see all of our great woodworking tools!