Do you need a table saw crosscut sled? Every table saw I've purchased came with a very nice rip fence, and a barely adequate miter gauge. Should I assume that table saws are designed more for ripping? Seems like I do an awful lot of crosscutting and mitering on my saw! And while a better miter gauge is a good idea, I like an upgrade to a crosscut sled.

I’ve worked with simple sleds that were a piece of plywood, a screwed-on hardwood fence, and a miter bar on the bottom. And also some very fancy sleds with more add-ons than a Swiss Army knife! I think the new Professional Crosscut Sled from Infinity finds the sweet spot in the middle!

Start with a Stable Base

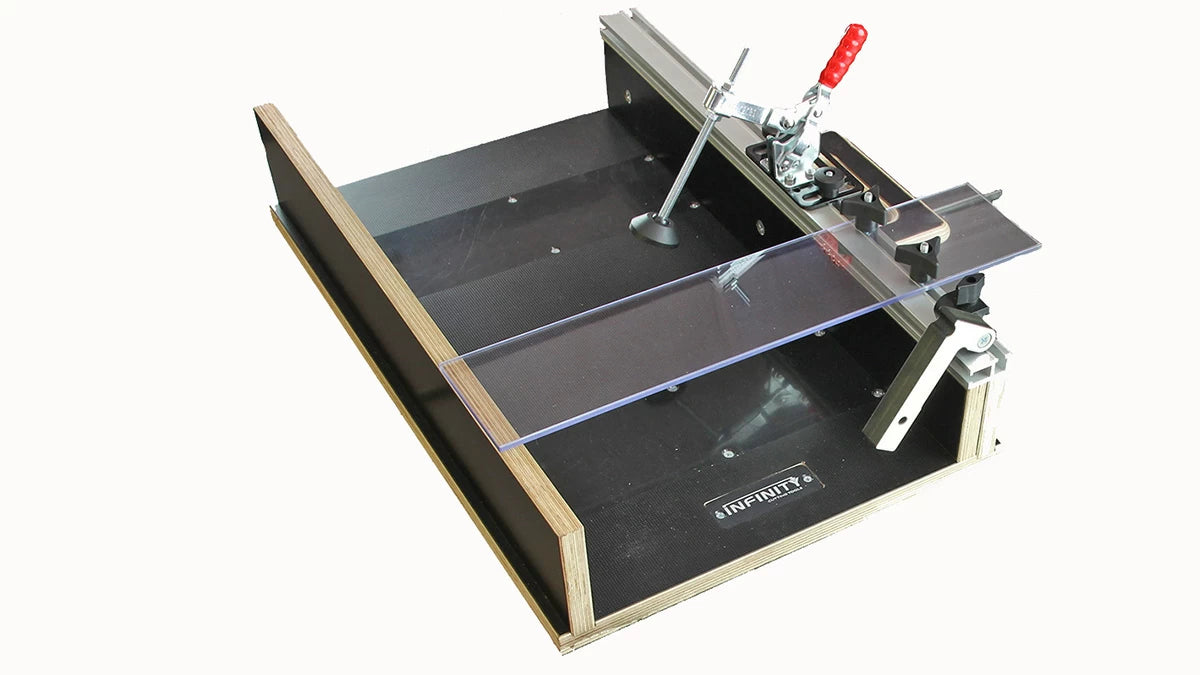

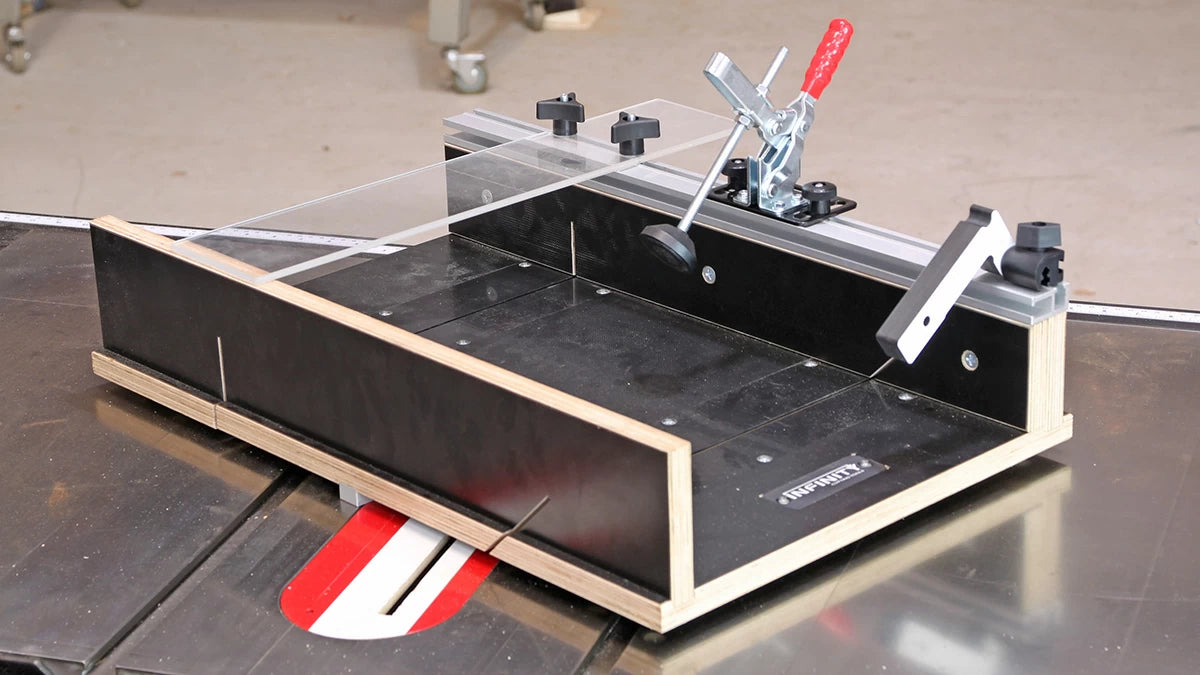

You want a stable platform that’s large enough to support a good sized-board, both in capacity and while cutting. The TCS-100 is deep enough to crosscut a 12”-wide board. And the nearly 24” width provides support on both sides of the blade. I’d call that a perfect size. Wider than that and you could simply use your rip fence. But less than that width you need the safe and stable support of a crosscut sled.

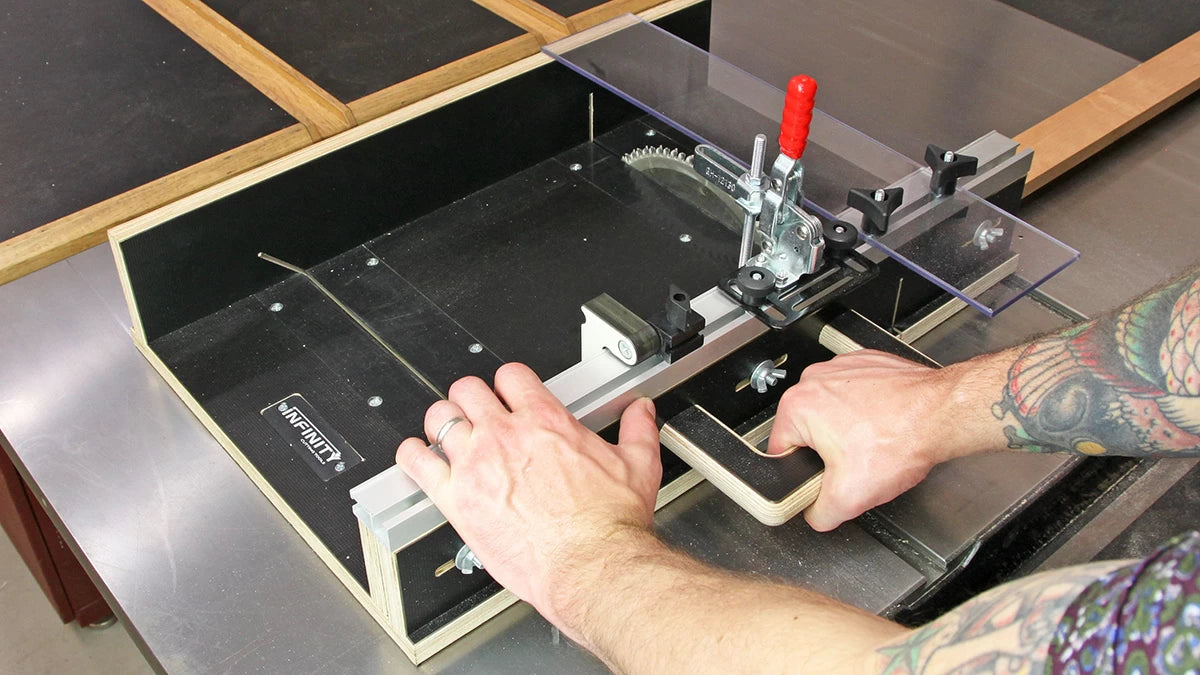

The core of the sled table is constructed from ¾”-thick, void-free, high-density plywood (the best and most stable option for jigs and fixtures!). The underside sports melamine laminate to let the sled move more easily over the table saw’s surface. And the top side of the table has a MicroDot laminate coating that creates a low-friction surface for easily adjusting workpieces.

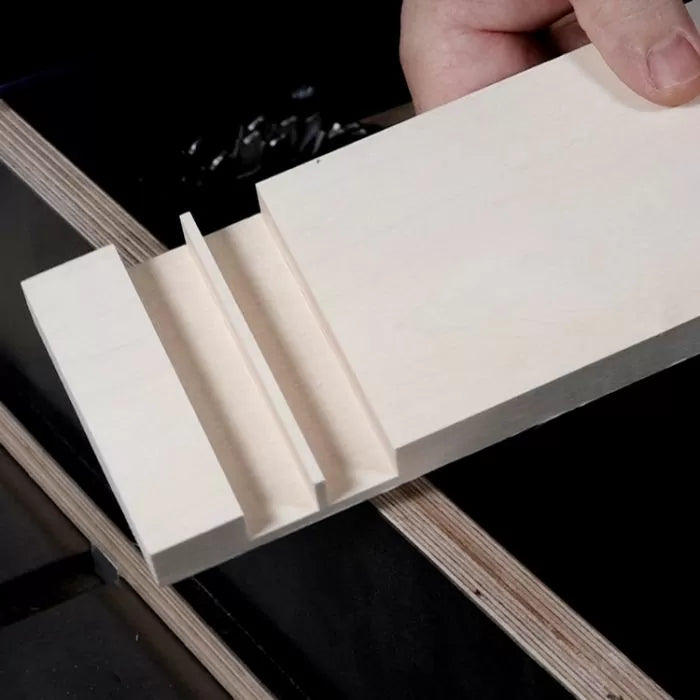

The TCS-100 has one miter bar that uses spring-loaded ball detents to adjust for a tight fit in nearly any miter slot. The table saw crosscut sled can be repositioned to the miter slot on either side of the blade allowing for two cutting areas on the sled. Both of these cutting locations feature replaceable HDPE Zero Clearance Throat Plates. One plate can be set up for 90° cross cuts, while the other can be set up for miter cuts — or even a dado stack — simply by switching slots.

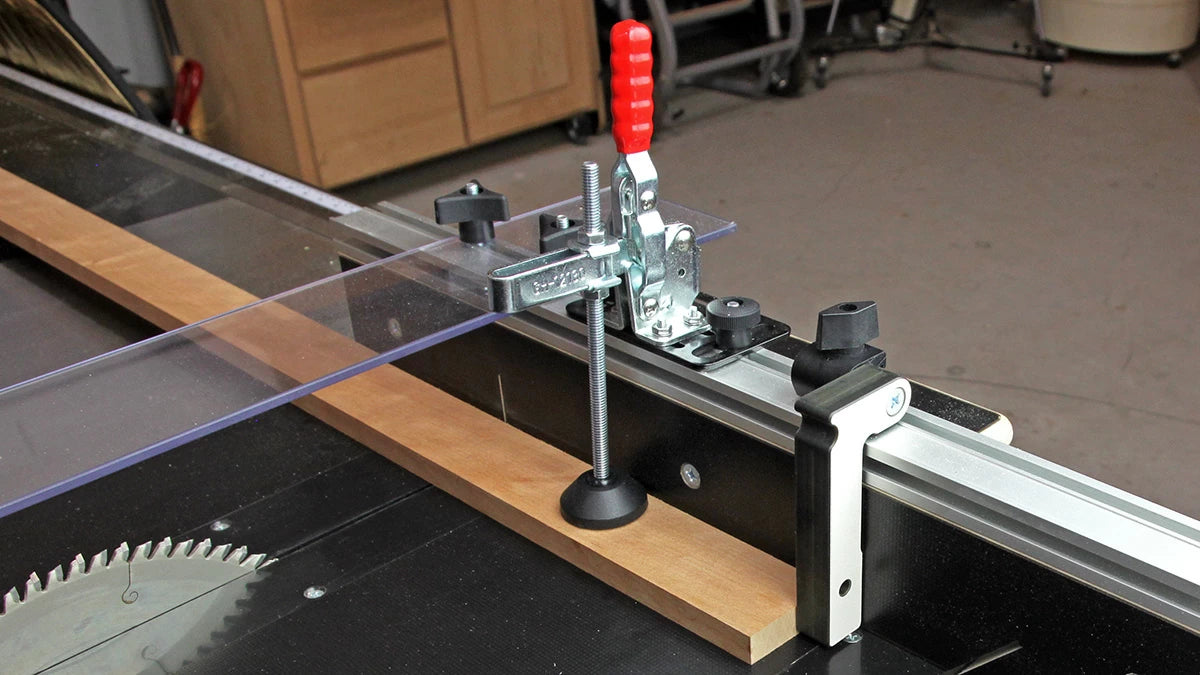

The front and rear fences mount in precisely-machined slots in the sled base. These slots are squared to the sled, providing even greater accuracy. A sacrificial (and replaceable) fence is mounted to the rear fence and a quality extruded aluminum top rail is mounted to that. Our unique deep-throat hold-down clamp solidly mounts to the top rail — with 500-lbs of holding power — to keep your cuts accurate and prevent drop-off pieces from tilting, negating the need for a separate offcut platform.

Accessories Make the Sled

The top rail also provides mounting locations for the removable blade guard. The guard is great for deflecting chips and helps keep your hands safely away from the blade. The precision flip stop can be positioned anywhere along the fence for accurate repeat cuts.

The robust handle makes it easy to move the table saw crosscut sled. And when you're done using the sled, the handle will even double as a convenient hanger for storing!

Replenishable Resources

Table saw crosscut sleds get cut up in use. That’s why I’m particularly fond of the available replacement kit (Part # TCS-200.CRP). The kit includes another sacrificial rear fence and two additional throat plates. Not only good for when the sled is showing wear, but the extra throat plates make it easy to keep zero clearance tolerances for a number of cutting operations.

If you’re looking for a sensible upgrade for your table saw, look no further. The Infinity Table Saw Crosscut Sled has the capacity and features you need, and the accuracy you require!