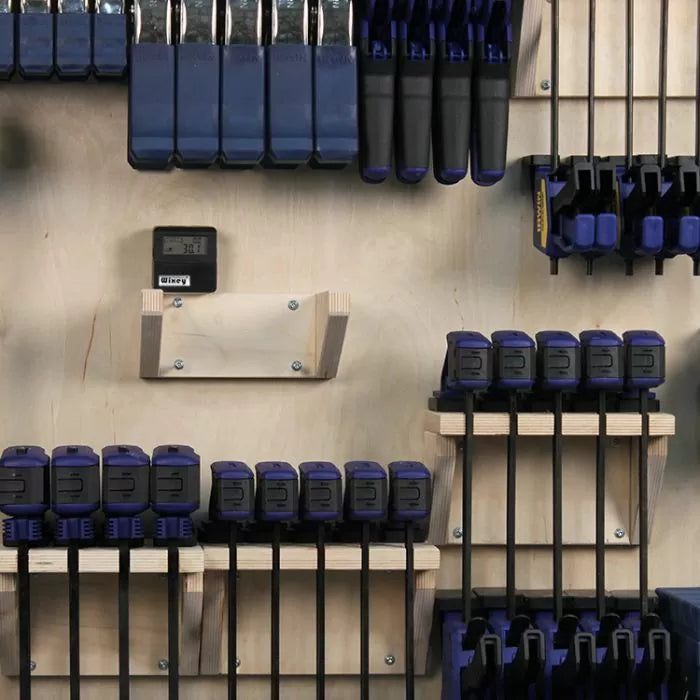

While I wholeheartedly agree with the old saying that you can never have too many clamps, you definitely can have more clamps than your clamp rack can hold. This was the case in our shop here at Infinity Tools with our old clamp rack, especially when we added some new Irwin clamps to the mix. We decided it was time for a new rack. And that rack needed to be able to hold all of our clamps and hopefully have some room to grow.

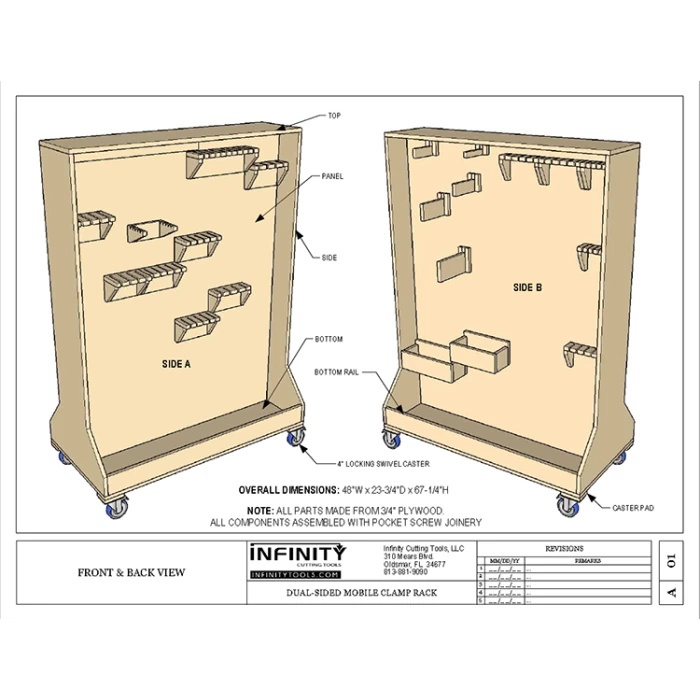

Click here to download measured drawings!

The first goal was to ensure that the rack was easy to build from readily available material. 3/4" plywood components assembled with Kreg pocket screw joinery fit the bill. Crosscutting the first piece of 4' x 8' plywood into three pieces at 5', 2', and 1' long creates all but the two sides of the rack. The rest of the parts (sides, rails, etc.) can easily come from a second piece of 3/4" plywood which makes this a fairly economical project as well.

To cut the plywood, I found it easier to use a track saw rather than try to wrestle the sheet on my table saw.

For mobility, I scavenged the casters from our old clamp rack. I prefer to use casters 4" in diameter or larger for both load capacity and ease of moving the rack on a dusty, uneven shop floor. Better still, invest in locking swivel casters for greater mobility.

The brackets that hold each style of clamp on our rack are designed to be modular. They fasten to the partition of the rack with pocket screws so that they can be placed wherever needed in order to make the most of the real estate available.

Depending on the size of the clamp, I made kerf cuts in the brackets so that the clamps would notch into place and stay secure and organized even when the cart is moved around the shop. I found that the majority of the Irwin clamps fit perfectly into a 1/4" kerf made with an Infinity 1/4"-kerf flat-top blade, but a few of the heavy-duty clamps require a 3/8" kerf which are easily made with an 8" Dadonator stacked dado blade. (Note: You'll need to use an 8"-diameter or larger blade for the depth of cut required to create the slots for the clamps.)

Most of the brackets consist of a slotted top, a pair of triangular supports, and a back. All are joined with pocket screws.

Besides storing clamps, there's another advantage to the clamp rack's modular design: Custom storage for accessories. I built a couple of trays and installed them at the bottom of the rack to hold various tools or accessories. The top of the rack can easily be turned into a shelf or bin to further expand potential storage.

The trays are fastened to the back wall to hold things like our Kreg Jig and glue bottles, both of which go hand-in-hand with clamping. A few bins to hold various types of screws and hardware would be a good addition, as well.

We're so happy with the way this project turned out that we decided to offer it as a plan on our website, and we even created an Irwin Clamp Package that includes almost all the clamps that have found a home on the rack. Whether you need to outfit a new shop, start fresh and make sure you have your clamping bases covered, or want to add some clamps to your collection, building this clamp rack is a great place to start.