I've used this saw almost more than any other saw in my shop. As a matter of fact, I use it so often, I bought a second one. I keep one in my shop and the other in my tool bucket I use for household chores and repairs. I use it for trimming joinery, cutting plug and dowels to length, cutting door jambs to fit flooring underneath, and a whole host of other tasks. The blade is thin and flexible, so it's ideal for these jobs. I've had these saws for years and have yet to replace the blades because the impulse-hardened teeth seem to last forever.

The purchase of this little saw got me started down the road of using pull-saws, or Japanese-style saws. They take some getting used to, especially if you've grown up with Western-style saws, like I have. Truthfully, I have a mix of both Western-style and pull saws in my shop. But I'm finding myself reaching for the pull saws more frequently.

Pulling Teeth

Pull saws, as the name implies, cut on the pull stroke. This differs from Western-style saws that cut on the push stroke. And because they cut on the pull stroke, the blade is always in tension. This means the blade can be a lot thinner. It's like pulling on opposite ends of a piece of paper — as long as there's tension, the paper remains taught and straight. The same principle works on a pull saw blade.

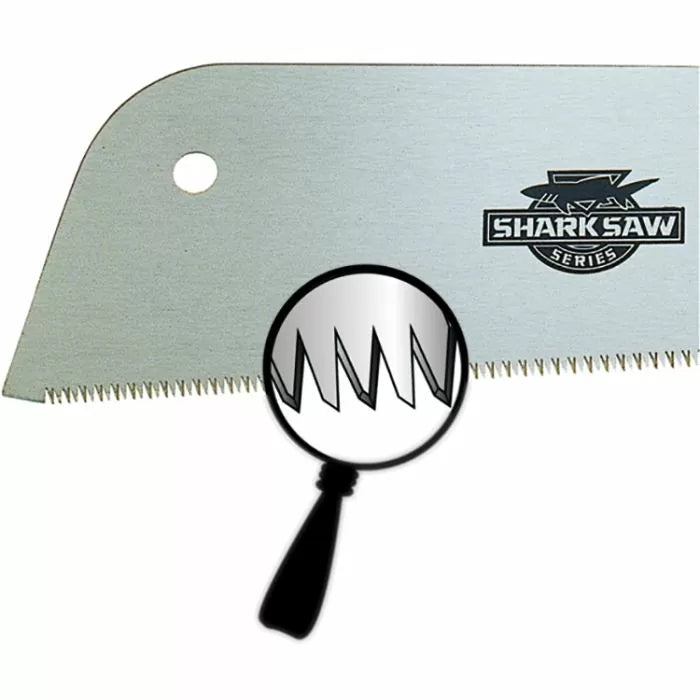

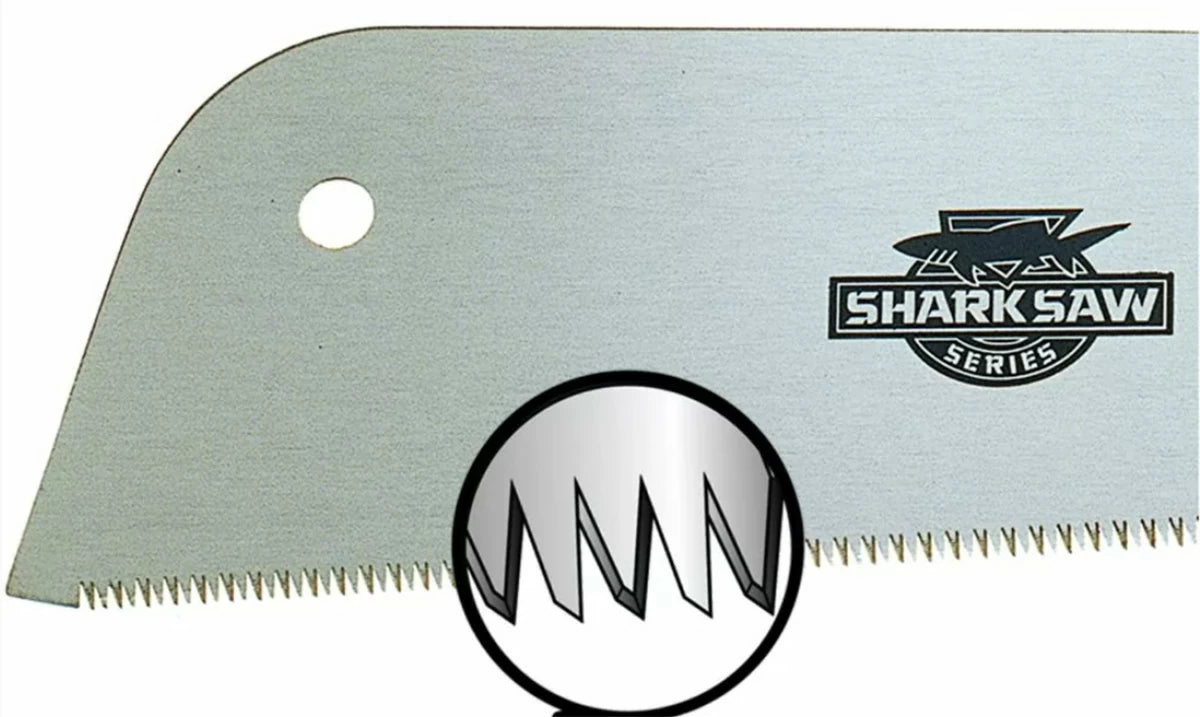

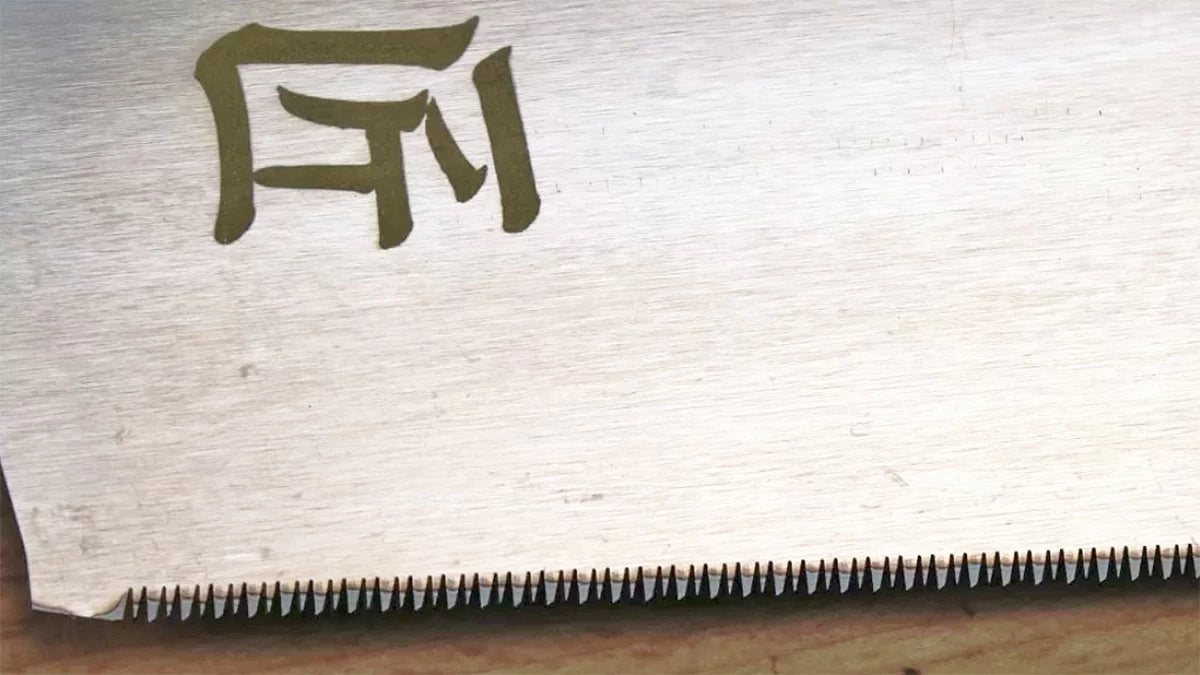

Infinity Cutting Tools offers a series of saws from Shark Corporation. The blades are made of high-quality Japanese steel specifically sharpened for fast, smooth cutting. The "SharkSaw Series" brand features non-slip handles for comfort. The more traditional Japanese-style "Takumi" brand of saws utilize a wood handle wrapped in rattan.

The teeth on the Shark saws are specially ground with a diamond pattern to create three cutting edges. They excel at crosscutting but do an excellent job of ripping, too. Most saws have a "set" to the teeth. This means the teeth are bent slightly in an alternating pattern. This ensures the cut is wider than the saw plate to prevent binding during the cut. Some saw manufacturers also taper-grind the blade so that it's thinner along the edge opposite the teeth.

Because the steel on pull saws is so much thinner, you'll find that the set on the teeth is much less dramatic than you'd find on Western-style saws. This has the advantage of creating a very thin kerf that requires much less effort when sawing.

Using a Pull Saw

If you've never used a pull saw before, let me just give you a word of warning: Don't jump right in without practicing on some scrap material first. If you try to use a pull saw as you would a traditional Western-style saw, you'll likely do what I did the first time and bend the thin blade, creating a kink which renders the saw useless.

Pull saws were originally designed to be used with two hands. Traditional Japanese woodworkers sit on the floor at a low bench and use their feet to hold the workpiece. This position lends itself well to using a saw on the pull stroke. Sometimes they'll stand and use the saw on the workpiece positioned at their feet, still using two hands for a smooth, straight cut.

Western-style saws, on the other hand, are designed to be used with one hand. Their stiff blades lend themselves to one-handed use on the push stroke. As I mentioned, a pull saw requires a different technique and some practice.

The first thing to note is that you don't need to force the saw into the cut. Generally speaking, the weight of the saw itself, with its razor-sharp teeth, is sufficient to do the cutting. A light touch is all that's required. So relax the death grip.

The critical component in your technique is to ensure the blade travels in a straight path throughout the stroke. Any side-to-side deviation risks binding the blade or worse, bending the blade. Whatever technique you find that works for you to accomplish goal will produce better results and smooth, straight cuts.

A Hybrid Blend of History and Technology

I like to think of the Shark pull saws as a blend of ancient Japanese tool-making craftsmanship and modern technology. They use Japanese steel that is precision-ground and machined to create super-sharp teeth. Then, in most cases, the teeth are impulse-hardened to create long-lasting, tough cutting edges that can last for years before the blade needs replaced.