Woodworking Safety Day. Woohoo, let's celebrate. Oh, wait. Today is not a holiday, but a reminder to take the time and go out to your shop and make sure you are using the best possible practice in your safety procedures.

Shop Safety is something we at Infinity Cutting Tools take seriously because almost every woodworker has a story of what happened to them or a friend, yet we all still go and rush through a project or two. All the stories talk about how it happened so quickly, yet we are sure that it will never happen to us.

My worst injury came on a miter saw. I was cutting radius stops for an arched-top radius door. I had done this hundreds of times. You lay your curved profiled piece of wood against the fence and figure out your angle. You lay some scrap blocks on the back of the curve to keep it from getting pulled or yanked. Yup. I was in a hurry and decided that the little bit I was cutting wouldn't need a backer block. When the blade hit the radius stop, it jerked it through the palm of my hand and I had an awesome cut through my fingers and palm. I was out of work for a few weeks. Let's celebrate.

Injuries do happen. They are almost always preventable. Best Possible Practices. What I mean by this is go out and do what you know you need to do to be safe in your shop. We know we need our safety glasses or over-the-glasses safety glasses. We know we need ear protection. We know we should use dust masks and/or respirators. Wear them. Use them.

We want to talk about some of the easy things you can do to be safe.

- Keeping your tools sharp. A sharp tool is much safer as it requires less energy to push wood through.

- Tuning up your equipment. Make sure fences are square and belts are tight. Every now and then go through and tighten bolts.

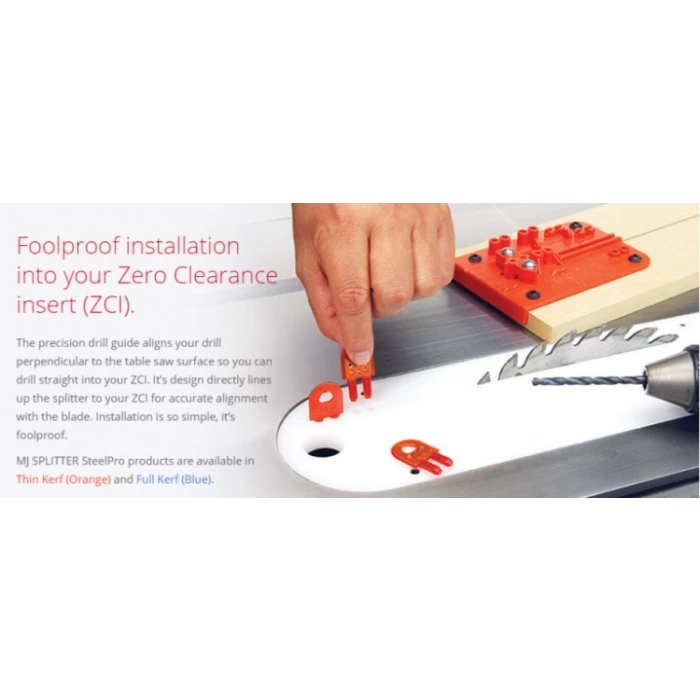

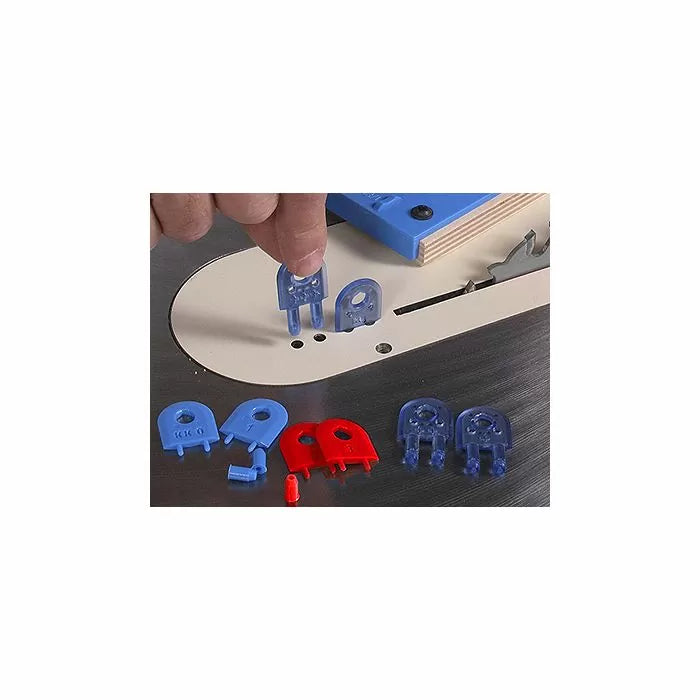

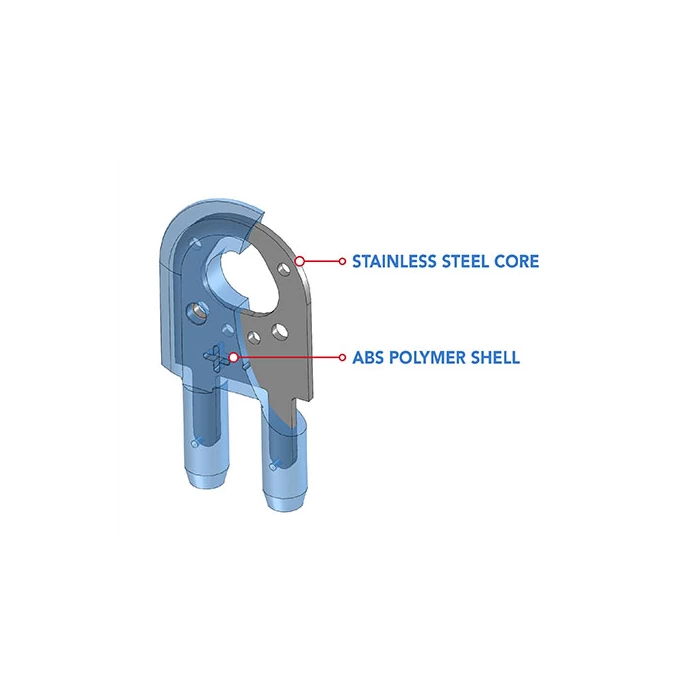

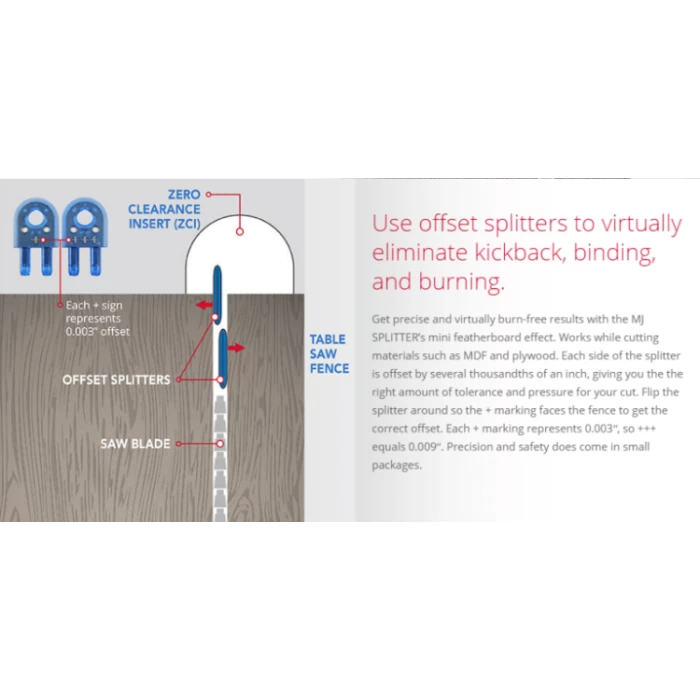

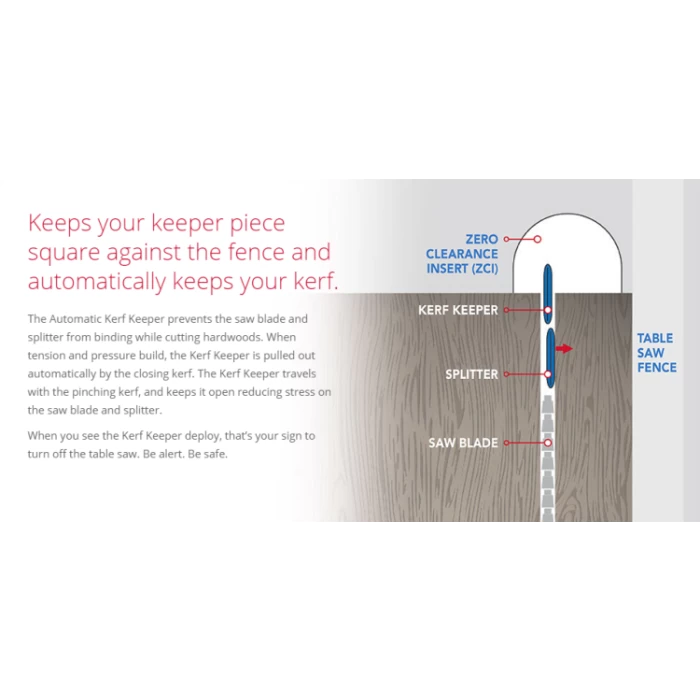

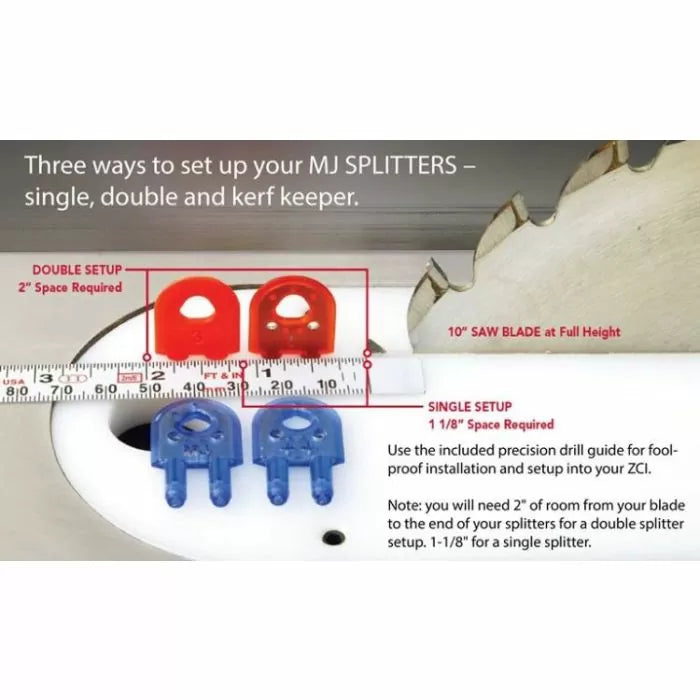

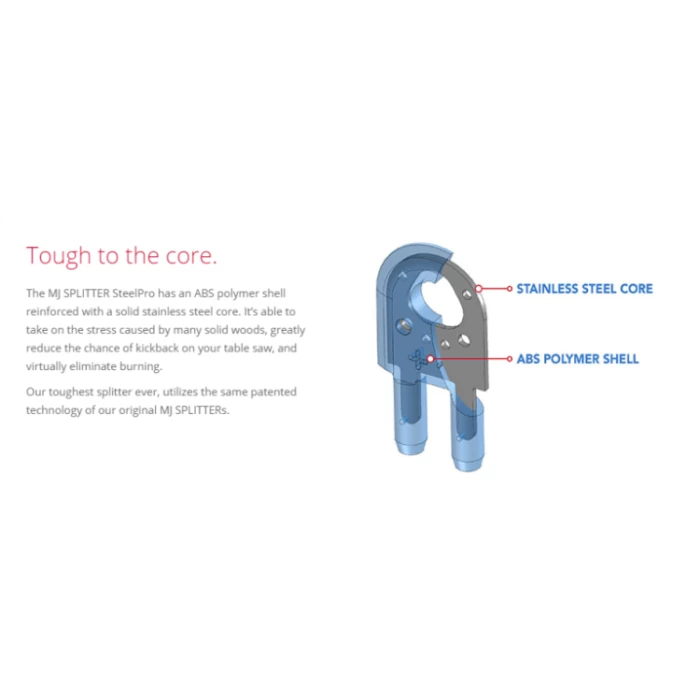

- Table Saw Safety. Use a riving knife or splitter on the table saw.

- Electrical Safety. Unplug equipment when you are working on it.

- Sixth Sense. If you think you shouldn't do something, don't do it.

- Take Your Time. Don't rush woodworking. Enjoy it.

- Use Safety Equipment. Use jigs, push sticks, sleds, and featherboards to keep your little fingers away from the sharp, pointy stuff.

Best. Possible. Practice. It only takes a minute.