8-Pc. Precision Setup Blocks

Take the guesswork out of setting router bit heights, fence locations, and table saw blade height with our precision-milled setup blocks. The eight-piece set includes the black anodized aluminum blocks with contrasting laser-etched scales as a set.

Anyone that knows me or has been in my shop knows that I'm a tool junkie, especially when it comes to measuring, marking, and layout tools. I've got so many tools that I'm often surprised when I open a drawer and see tools I've forgotten I had.

When I had the opportunity to collaborate on the design of some precision setup blocks for Infinity Cutting Tools, I was excited. We had several meetings to discuss what would make the ideal setup blocks for a woodworking shop.

Designing a Set of Setup Blocks

We started with the material. We chose aluminum because it's friendly to the sharp edges of tools. Once we made that decision, we knew we had to add a coating of some sort. There was no other choice than black anodizing. It makes the graduations on the scales much easier to read (more on that later). Plus, black is Infinity's color. Another benefit is that the anodizing adds durability.

With the black anodizing selected as a finish, we immediately thought of all the possibilities for laser engraving. Which then led to a discussion of what would be an appropriate size for the setup blocks. We chose 3/4" wide stock because it's easier to grasp for tool setup and layout work. Then we thought a 4" length would be appropriate, especially for those of us with bear claw hands. Ours are the longest setup blocks on the market.

The next decision was to decide what thicknesses of setup blocks to offer. We wanted to cover a wide range of measurements without getting carried away with the number of blocks required. So we settled on 7 thicknesses:

1/16", 3/32", 1/8", 3/16", 1/4", 1/2", and 3/4"

This provides a range from 1/16" to 1-31/32" in 1/32" increments. The thickness of each of the blocks is machined to within 0.002" accuracy.

But we didn't stop there. We're also including a 1-2-3 block. Machinists are familiar with this type of setup block for setting up machinery. Our 1-2-3 block is machined from solid aluminum then black anodized. The 1-2-3 block, in combination with the setup blocks mentioned above, extend your range of measurement to 4-31/32" if you use all of the blocks in combination.

But let's get back to all of that black anodized real estate on both sides of the seven 3/4" x 4" blocks. With laser etching, the possibilities were endless. So we decided to add inch scales not only along one long edge of each block but also the ends. This feature alone makes them perfect for setting-up woodworking tools like router bit and saw blade heights. We're the only company that goes to the trouble of laser-engraving scales on each of the setup blocks.

On the opposite face of each block, we've etched the thickness of the block in a large, easy-to-see font. This way, you can easily grab the block you need without guesswork.

While we were at it, we decided to add some scales along two edges of one of the large faces of the 1-2-3 block. We're sure you'll find all sorts of uses for this feature.

Using the Precision Setup Blocks

So what can you do with these precision setup blocks? Here are just a few uses I can think of, but the possibilities are endless:

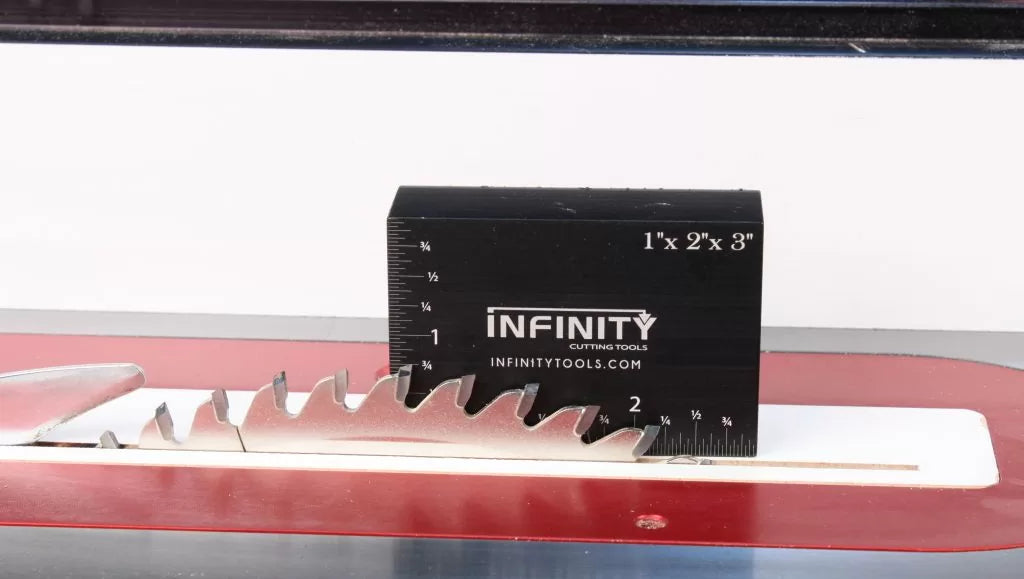

Setting table saw blade height

The inch scales on the 1-2-3 block are handing for setting the blade height at the table saw.

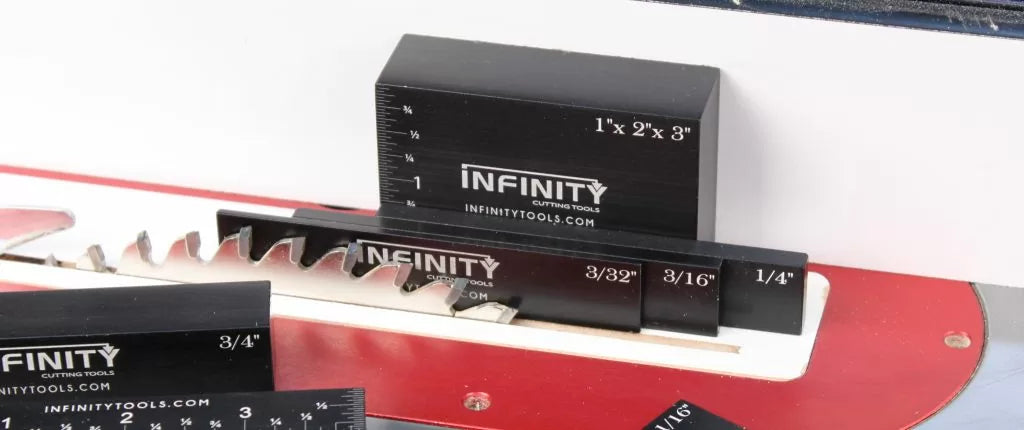

Setting table saw rip fence position

Stacking setup blocks with the 1-2-3 block extends the measuring range. Here, the 1-2-3 block is being used to add 1" to the 3 setup blocks shown.

The 1-2-3 block is being used to add 2" to the 3 setup blocks shown.

The 1-2-3 block is being used to add 3" to the 3 setup blocks shown.

Setting router bit height

The scales on the ends of each setup block are convenient for checking the height of the router bit in the router table.

Setting router table fence position

Placing the setup blocks between the router fence and bit at the router table make it easy to set the fence distance from the bit.

If you want to set the router table fence distance from the outside of the bit, simply use a straightedge aligned with the setup blocks as shown.

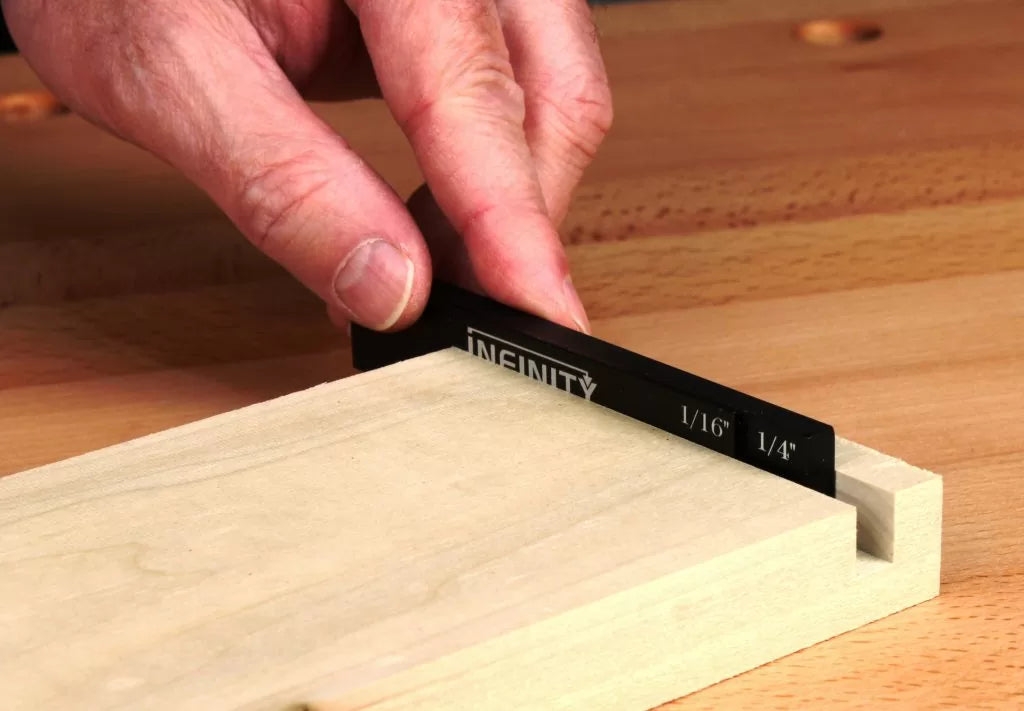

Checking dadoes, groove, and rabbets for proper sizing

Use the setup blocks to check the width of dadoes and grooves.

The inch scales on the setup blocks make it easy to check the depth of dadoes, grooves, and rabbets.

Checking the depth of mortises and drilled holes

Verify the depth of drilled holes and mortises using a setup block.

Layout work on smaller projects

Each setup block becomes a handy rule for layout tasks on smaller projects.