3-Pc. Ultimate Glass Door Making Router Bit Set

Make custom glass doors with our exclusive 3-Pc. Glass Door Making Router Bit Sets! Available in six unique profiles, These router bit sets allow you to make the rails, stiles, and glass stop needed to complete your glass panel door project.

NOTE: Be sure to read Part 1, Part 2, and Part 3 on How to Build a Custom Cabinet.

A great way to add visual interest to your cabinet project is to use glass-panel doors for some or all of your upper cabinets. Glass doors allow you to display items inside the cabinets. We chose to add glass panel doors to a pair of our upper cabinets. The rest of the cabinets feature raised-panel doors.

Making the Door Frame

In the past, making glass doors meant using a traditional rail-and-stile router bit set and then rabbeting away the back part of the frame to make the rabbet to house the glass. Some router bit sets use a conversion kit that requires disassembly of the rail and stile router bits.

Our 3-piece Glass Door-Making Router Bit Sets eliminates the hassles of traditional rail-and-stile bits or conversion kits. The beauty of this router bit set is that it not only makes a perfect rabbeted frame for the glass panel door but it also forms the glass stop to hold the glass in place. Infinity offers five profiles that are a perfect match to our other rail and stile router bits.

Sizing the frame for a glass-panel door is no different than any frame-and-panel door. Start with the overall height and width you need your door to be. In our case the doors for our upper cabinets are 34-3/4" x 17". The width of our rails and stiles is a standard 2-1/2" wide. With this we know that our stiles will measure 34-3/4" x 2-1/2" . To figure out the length of the rails we subtract the width of the stiles from 17" which gives us 12". Add back the 7/16" overlap between the rails and the stiles. In this case, the rail length of 12-7/8" makes the final dimensions of our rails 12-7/8" x 2-1/2".

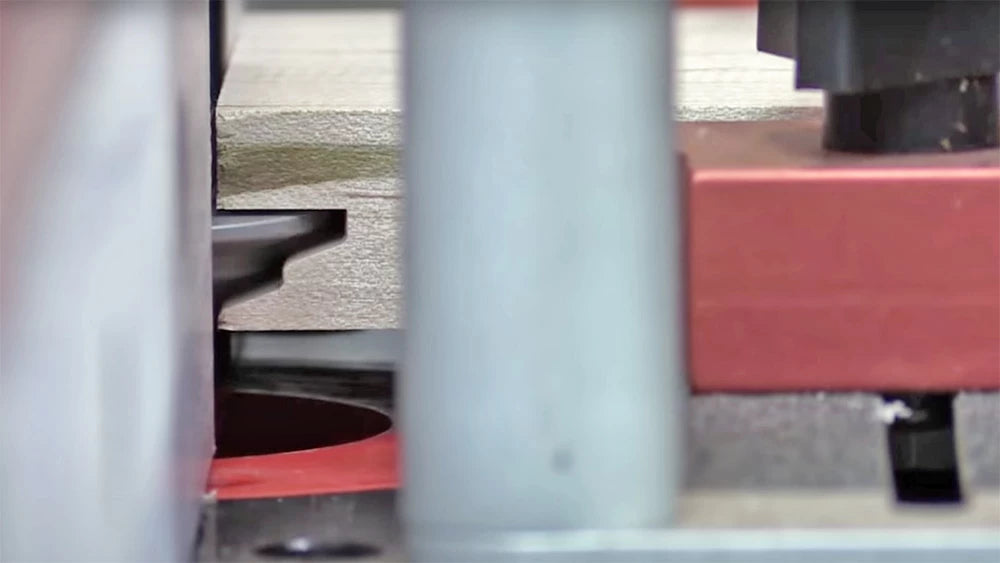

Using the 3-piece glass door router bit set is just like any other rail and stile router bit set but includes one extra step. With the frame pieces cut to size and width, I first mill the rail ends with the rail cutter and an infinity professional coping sled at the router table.

Once my rail ends are cut I switch to the stile cutter and mill the profile into all the rails and stiles.

Once my rail ends are cut I switch to the stile cutter and mill the profile into all the rails and stiles.

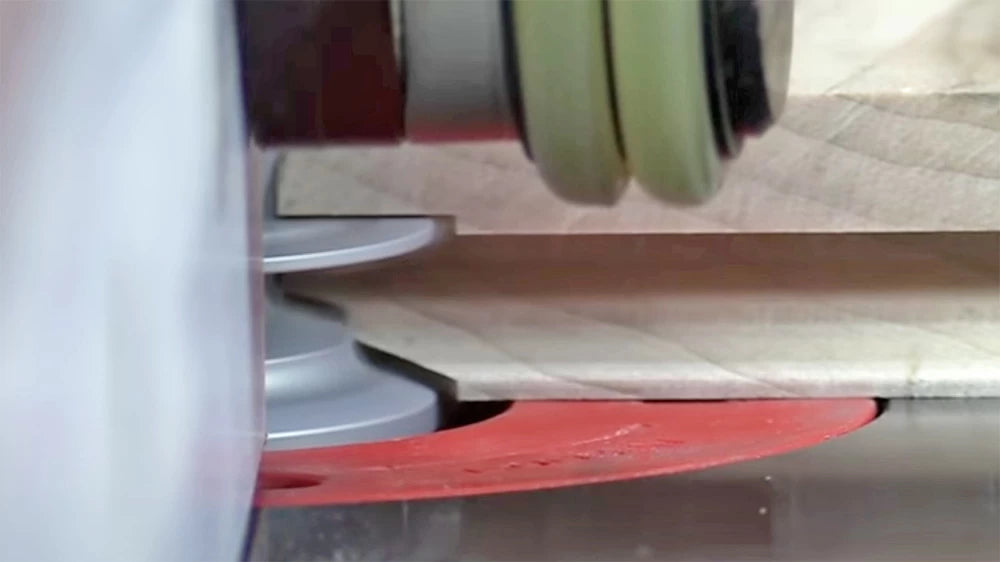

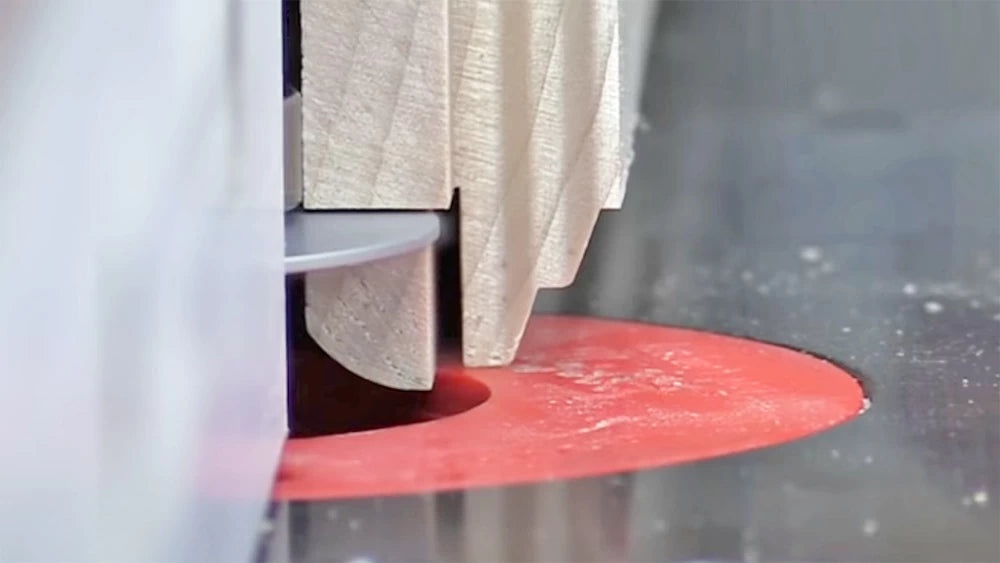

The Stile Cutter in the Infinity 3-pc. Glass Door-Making Router Bit Set creates the decorative profile, establish the base for the rabbet, and round over the back edge to produce the glass stop to retain the glass in the door. The Jessem Clear Cut Stock Guides are a must-have for jobs like this as they replace two sets of featherboards. At this point each piece will have its basic shape but will also have a round-over attached to the back of the frame pieces. To remove this round over and save it to be used as the glass stop I install the thin slot cutting bit included in the 3 piece set and slice the glass stop free at the same time creating the rabbet shoulder for the glass. Be sure when setting the height of this bit to match it perfectly to the base of the slot made in the previous step.

Setting the bit too low will cause the joints to not seat fully, setting the bit to high will cause a gap on the back side of the frame where the rails and stiles meet. Don't worry it may sound tricky but it is very easy using one of the rails or stiles as a setup block you can get the bit set perfectly on the first try.

With all the pieces cut It is time to glue up the frame. I recommend doing this on a nice flat surface and using Parallel-Jaw style clamps. This combination will help ensure that the frame comes out nice and square and without any twist. Because there is no panel installed the open frame is more likely to take on a twist during glue-up if you're not careful. I also double-check the diagonal measurements to ensure that the door a square before setting it aside to dry.

Once the doors are dry it is time to drill the mounting holes for the European-style concealed hinges. The Kreg Concealed Hinge Jig makes this very easy. It includes the drill bit needed to drill the 30mm pocket for the hinge body and also has guides to drill the 1/16" pilot holes for the two screws that hold the hinge in place. The jig has built-in stops that can be set to fit just about any type of concealed hinge and get it mounted in just the right place.

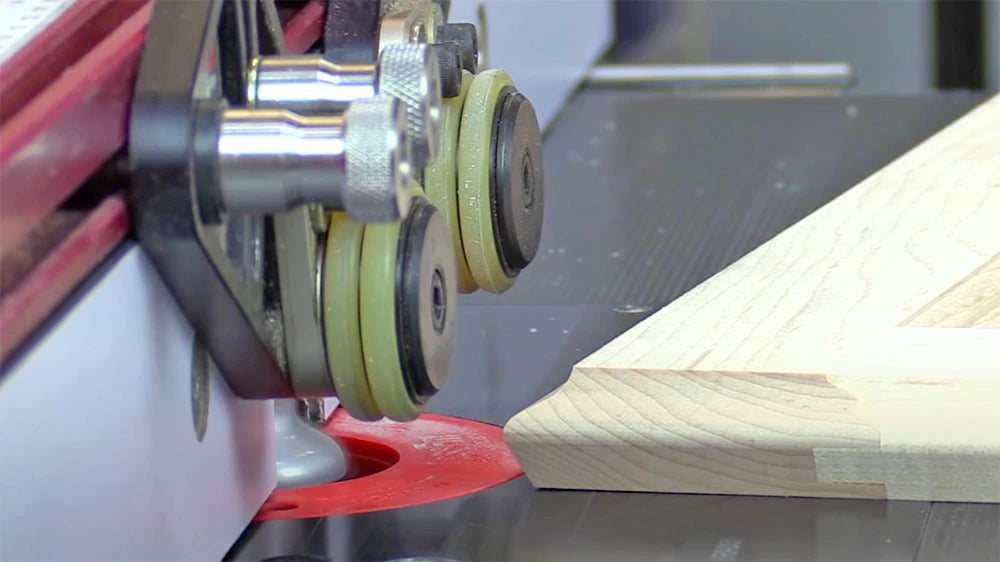

The last step is to mill the door edge profile onto the edge of all the doors to match our drawer fronts. I do this at the router table just like I did for the drawer fronts using a Door Edge Profile router bit (56-503). I do this after drilling the hinge pockets because the concealed hinge jig works best when referencing off of a square edge, if you try to drill the hinge pocket after milling the edge profile it can be difficult to position the jig consistently. I also recommend drilling the hinge pocket and milling the edge profile on a test piece to ensure that there is no issue with the depth of the pocket in relation to the profile on the edge of the door as the pocket could be deep enough that the profile mills into it and is exposed from the other side.

I typically wait till this point to order the glass for my doors this allows me to be absolutely sure that the glass I order will fit. Because the glass will not shrink and expand like a wood panel the glass can be cut to fit more tightly in the frame. I still like to size the glass about 1/8" smaller than the opening so that it does not bind and break. Installing the glass is straightforward, it can be installed dry into the frame and held in place with the glass stop strips we made with the 3 piece glass door-making set. I like to use a wire brad or small brad nailer to install the glass stop because they are a lot easier to use than a hammer when trying to drive the small nails right next to the glass. Using a small bead of clear silicone caulk as a bed for the glass is also not a bad idea. while we don't need to waterproof the door like we would a window the caulk will help insulate the glass from shock and keep it from rattling.

Because our cabinets are going to live in our shop where that glass is more likely to get broken than in a residence, we decides to use Plexiglas for our doors. We bought the Plexiglas in a big sheet and cut it down at the table saw using an Infinity Multi-Material Blade (010-380). The Multi-Material Blade is a really nice specialty blade to have around, it is designed specifically to cut all those unusual materials that you really do not want to cut with your fine tooth cross-cut blades. The Multi-Material Blade is an 80 tooth blade that has a triple chip grind and a negative rake that makes it ideal for cutting things like Plexiglas, MDF, and even aluminum extrusions.