Entry & Passage Door Router Bit Sets

These unique router bit sets let you build your own 1-3/8" interior & 1-3/4" exterior doors. Each set includes our 2-piece factory matched rail and stile cutters as well as a raised panel router bit in the corresponding profile. The rail and stile router bits cut both the decorative profile for the door frame as well as the cope and stick joinery that holds the entire door together.

Building an interior or exterior door can seem like a daunting task to a lot of woodworkers. But making your own door isn't as difficult as it sounds and it provides a lot of benefits. With the right tools and techniques, you can create the design that best matches your tastes, decor, and style of home. You can choose a wood species that complements the architectural elements of your home. Plus, you'll have the satisfaction of displaying your craftsmanship to everyone that passes through your entryway.

Part 1 - Preparing and Milling Lumber

I've been wanting to replace the old door between my house and garage workshop. Because the door leads into a dark hallway I wanted the new door to have a glass window to allow light to enter. The old door is an interior, hollow-core door 30" wide and 1-3/8" thick. (Most exterior doors in newer homes are 36" wide by 1-3/4" thick.)

This door separates my garage workspace from the climate-controlled house. I needed something to provide a little more insulation between the two spaces while displaying a design that better suited my tastes.

The only logical plan was to build the door myself. So, I want to step you through the process I used to build a custom-size, solid-wood door with insulated glass half-lite to fit the existing doorway opening. Walking you through this project should answer a lot of questions regarding interior and exterior door construction.

To build this door I used the Infinity Rail & Stile Router Bit Set for Entry & Passage Doors. These sets are offered in three different profiles: Ogee, Shaker, and Mission. I chose the Shaker profile (91-525) to create the rails and stiles of the doors. To create the raised panels, I used a standard-profile raised-panel router bit (90-502). These bits are shown in the photo below. The Shaker profile is one of my favorites and provides some flexibility to make it easier to fit raised panels and insulated glass into the thinner 1-3/8"-thick door. To provide strength to the rail and stile joinery, I wanted to create longer tenons on the rails. For this I used the 91-525TC Extended Tenon Cutter (also shown below). I'll talk more about this in Part 2.

I chose poplar lumber for this build. Poplar is inexpensive and readily available in 8/4 thickness and in wider widths. Poplar is also easy to machine and paint plus, it's not overly heavy. All the other doors in my house are painted so poplar was an easy choice.

The first step in building any door is to determine the size and design. The opening dictated the size and thickness and my desire for a window influenced my design. The design take a traditional 5-panel door and replaces the top three panels with a single, glass panel. This means that if I choose to replace other doors in my house I can make them in the same 5-panel design and they will look right at home. SketchUp is a great tool for laying out the door for the size and look I was after.

With the overall design nailed down I ordered the 8/4 poplar lumber and let it acclimate to the shop environment for a few weeks. Being 2" thick, I didn't want to rush cutting the wood and risk ending up with warped pieces. I gave the wood plenty of time to adjust to the humidity in the shop before diving into the build.

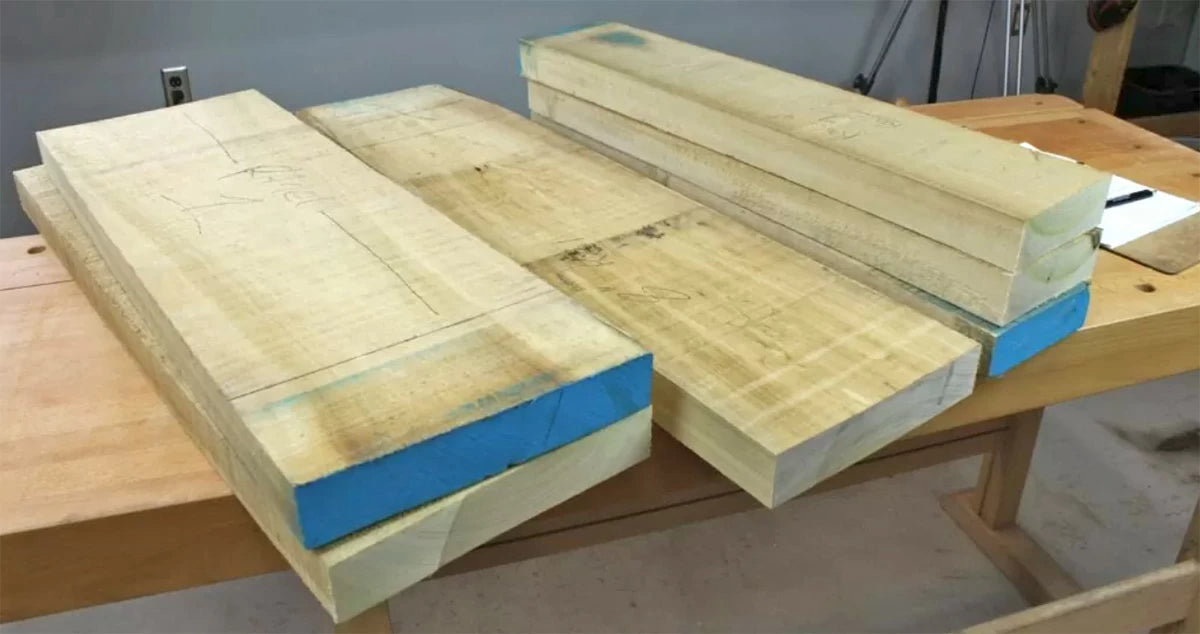

Rough-milling the lumber is the first step in the building process. I laid out all the door parts and cut each piece to rough length. It's important to leave enough room to trim away planer snipe and any possible checking or defects that might be present.

Next, I mill each piece to get smooth stock. The goal here is to get all pieces straight and square while getting rid of the rough-sawn surface. You'll want to leave a little material (about 1/4") so you can surface the lumber to final size after a few days. This helps eliminate any warping or twisting that might occur.

Milling rough lumber is straightforward, first flatten one face at the jointer. Then plane the opposite face in the planer. I like to joint one face first to remove cup, twist, and bow. The thickness planer makes the opposite face of the board parallel with the jointed face for an even thickness. Then it's back to the joiner to make one edge square to the faces and to create a nice, straight edge. The final edge is will be ripped straight and square at the table saw. Now our lumber should be smooth and square on all four sides but still slightly oversized.

With the rough milling complete and everything within 1/4" of final dimension I let the wood acclimate for a few more days before milling it to final size. For the final milling process I follow the same joint-plane-joint-rip process as before. This helps ensure all of the pieces come out straight and square. Because I'm starting with 2" thick rough lumber and finishing with 1-3/8" stock I try to take equal amounts of material from both sides to keep the tension in the wood as even as possible.

After milling to within 1/4" of final width and thickness, let the parts sit for a few days before milling to final thickness and width. You can cut the parts to final length at this time.

In Part 2, I'll talk about how to go about creating the joinery on the rails and stiles to create a rock-solid, durable entry door.