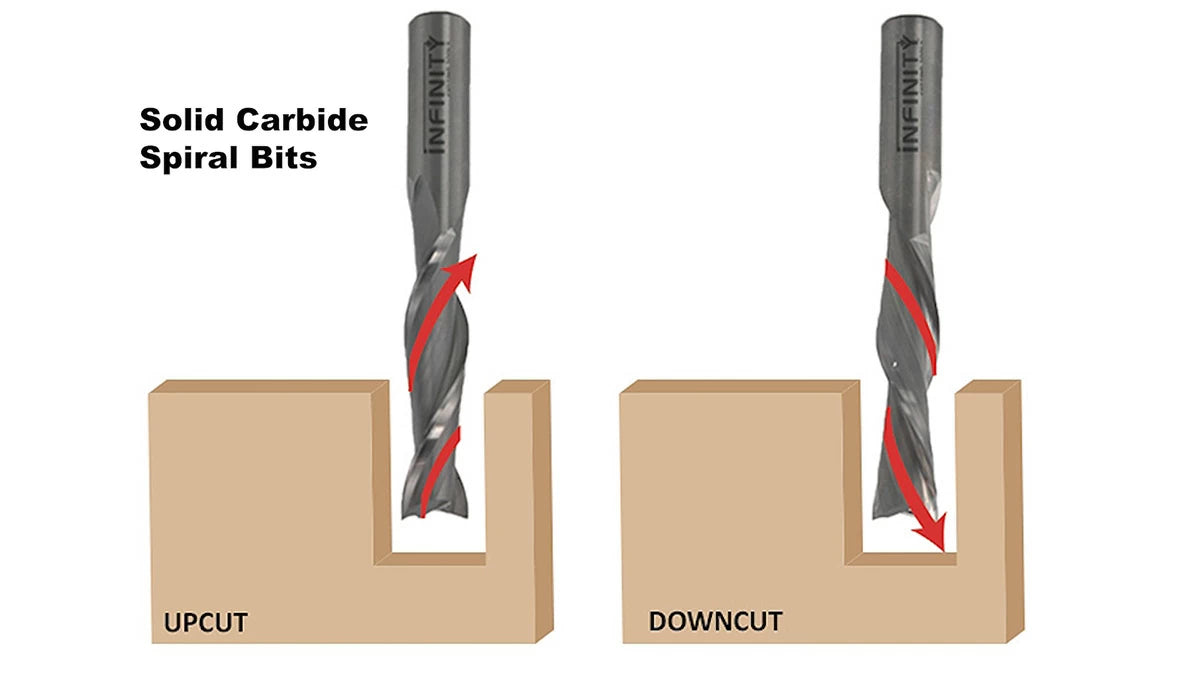

Many woodworkers are familiar with upcut and downcut spiral router bits, providing pressure either up, or down, to protect from tearout on delicate (veneered) surfaces as our most common in today's veneered plywood material. This works well if you're only worried about the top or bottom surface of your material. But if both surfaces will be visible, how to protect both?

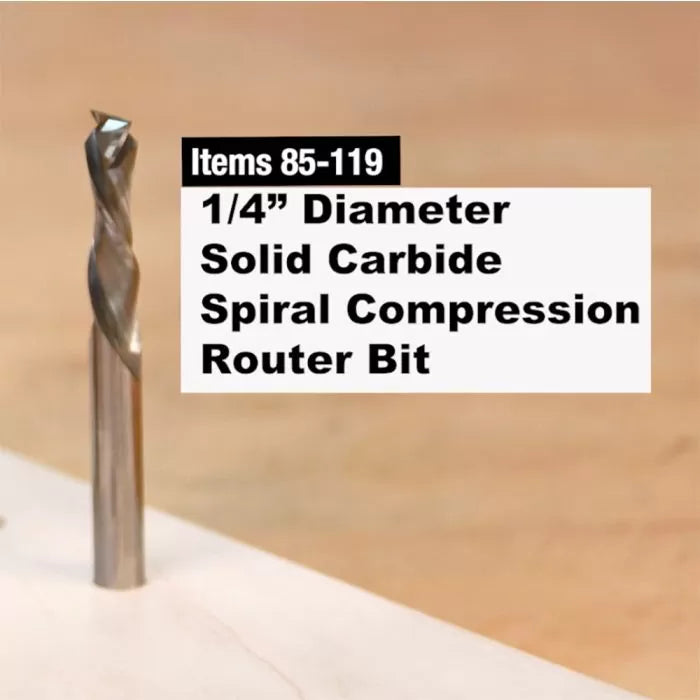

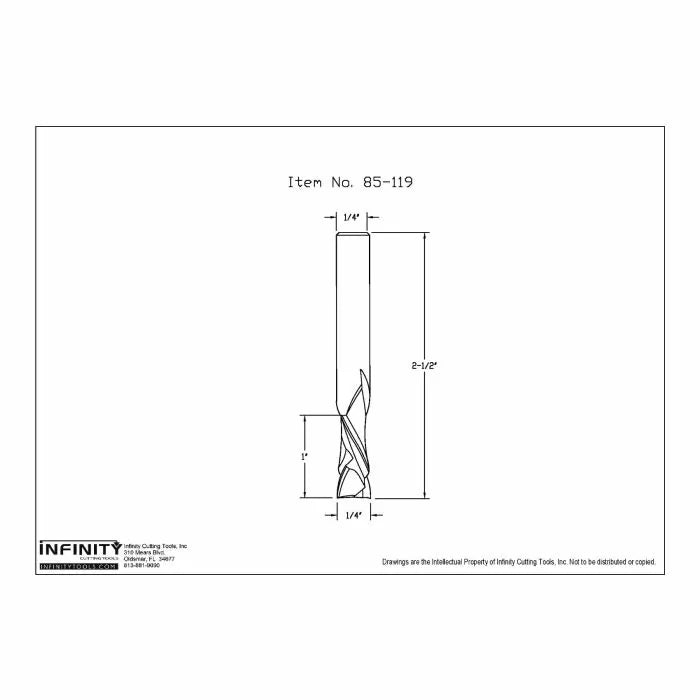

A compression bit is a spiral router bit that combines up cut and down cut action in one bit. The cutting tip pulls the fibers and chips up towards the center of the workpiece. The rest of the bit is cutting and pushing wood fibers down, also towards the center of the workpiece. Compression bits are definitely the way to go for getting clean top and bottom surfaces of your cut when used correctly!

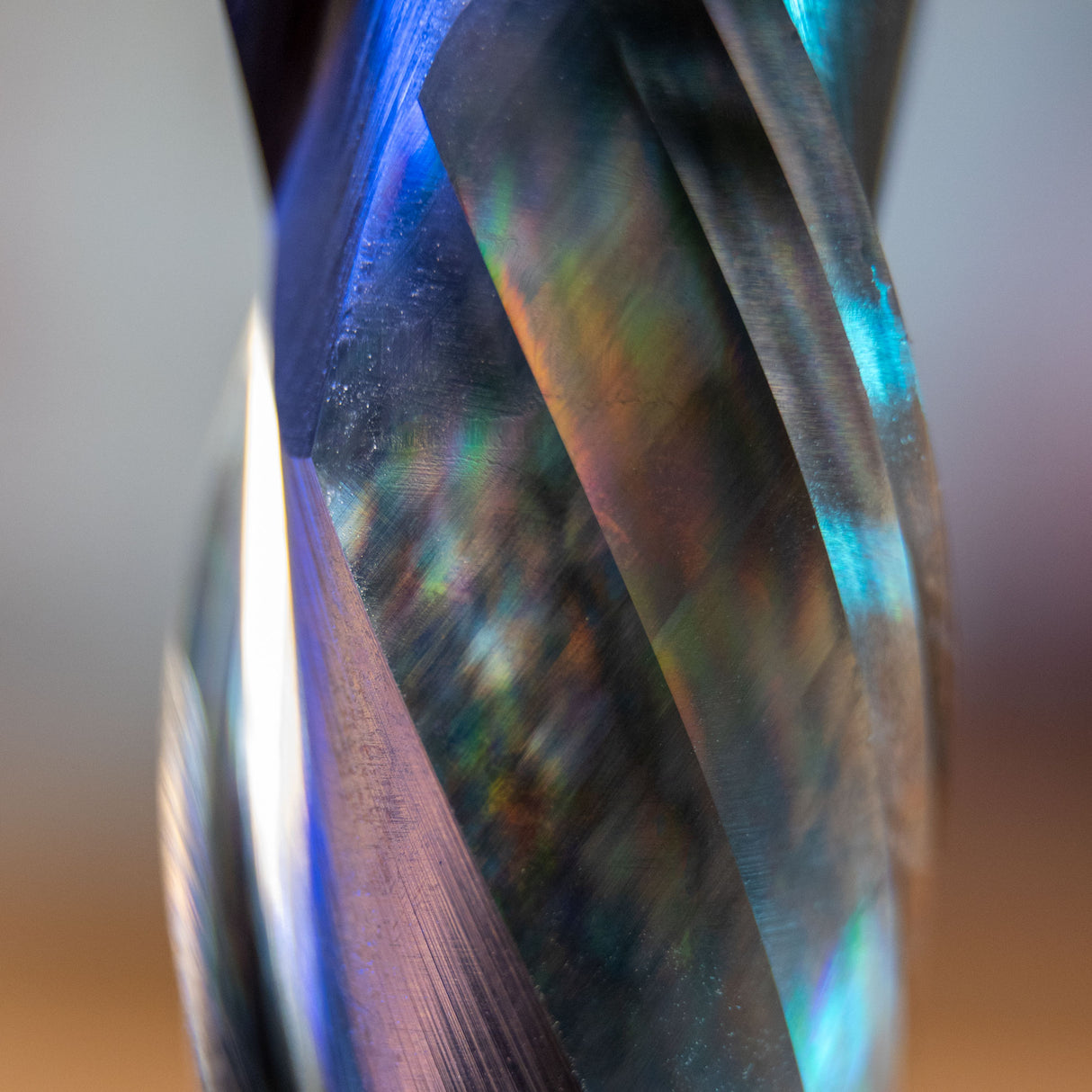

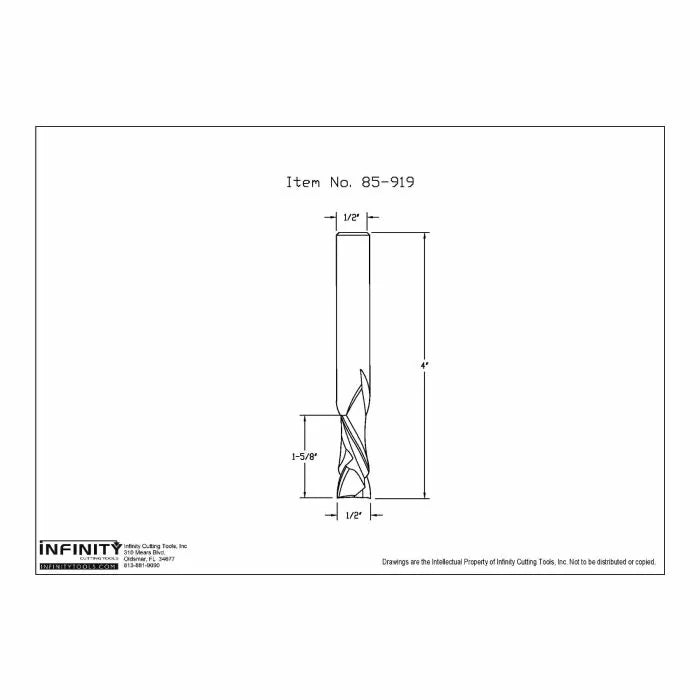

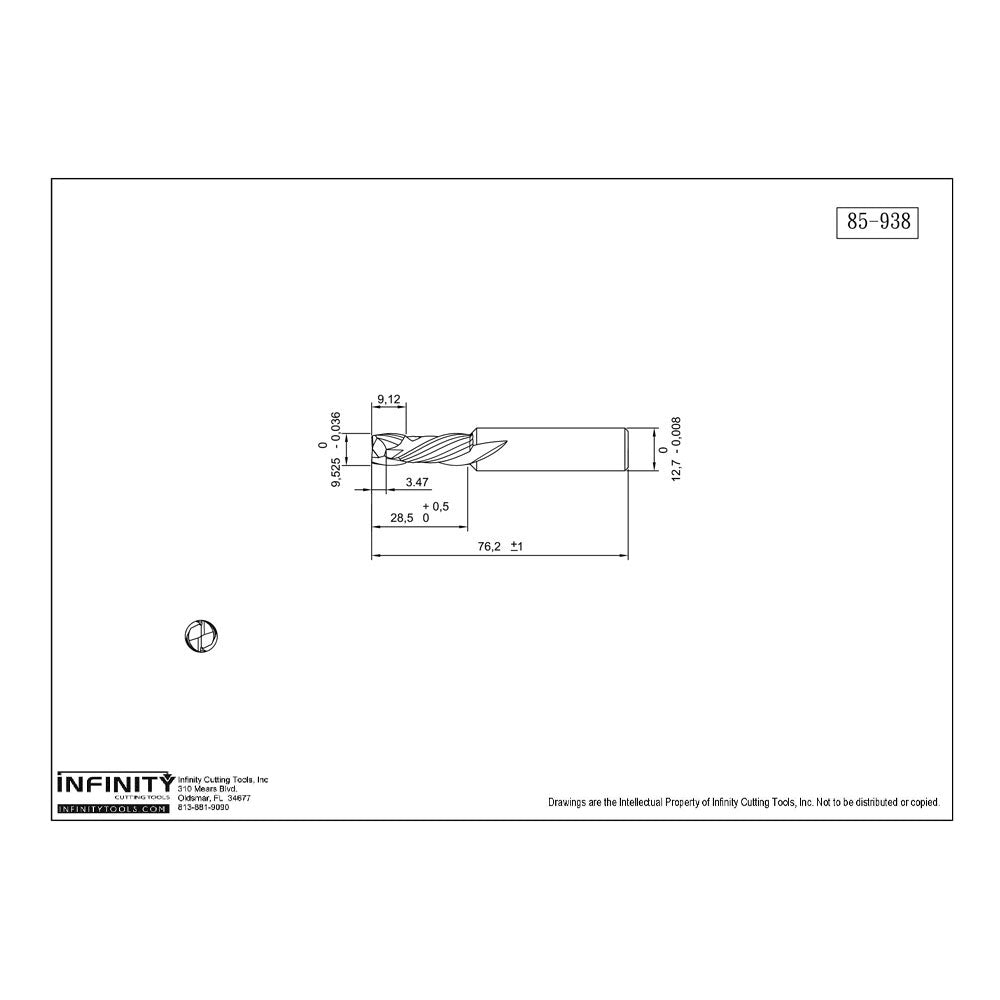

Our solid carbide spiral compression router bits are designed to provide remarkable performance and durability. They quickly slice through hard or soft wood, plywood and composites such as MDF or particleboard. Manufactured using state-of-the-art computer-controlled machinery; these micro-grain carbide cutters feature our optimal helix design and a stronger body that reduces vibration and lasts up to 300% longer than regular router bits. Unlike straight router bits, Infinity solid carbide spiral bits feature a helical spiral design that is continuously in contact with the workpiece, producing smoother cutting action and the cleanest results possible. They are available in both 1/4" and 1/2" shanks to best fit your needs.

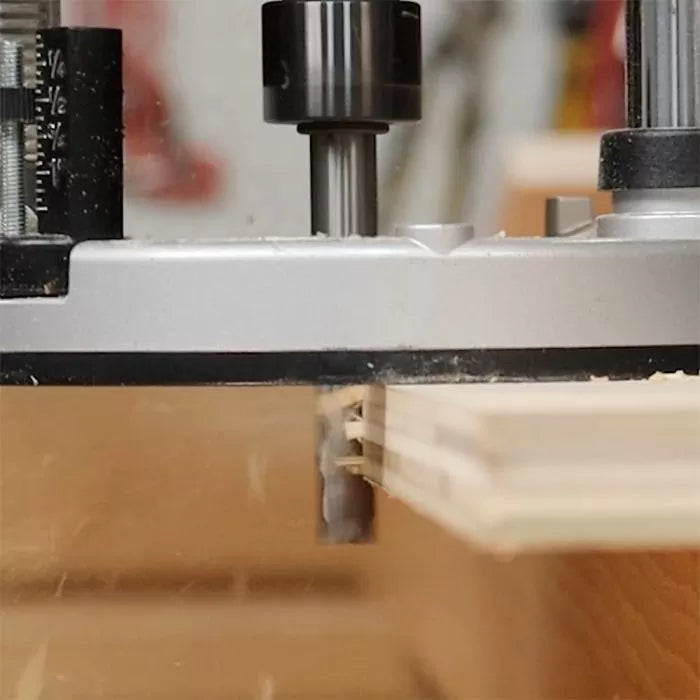

When adding a solid edge to a veneered plywood board, it's tough to get a clean edge with no tear-out. A solid carbide compression bit makes for a perfect edge without the need of any further edge or surface preparation.

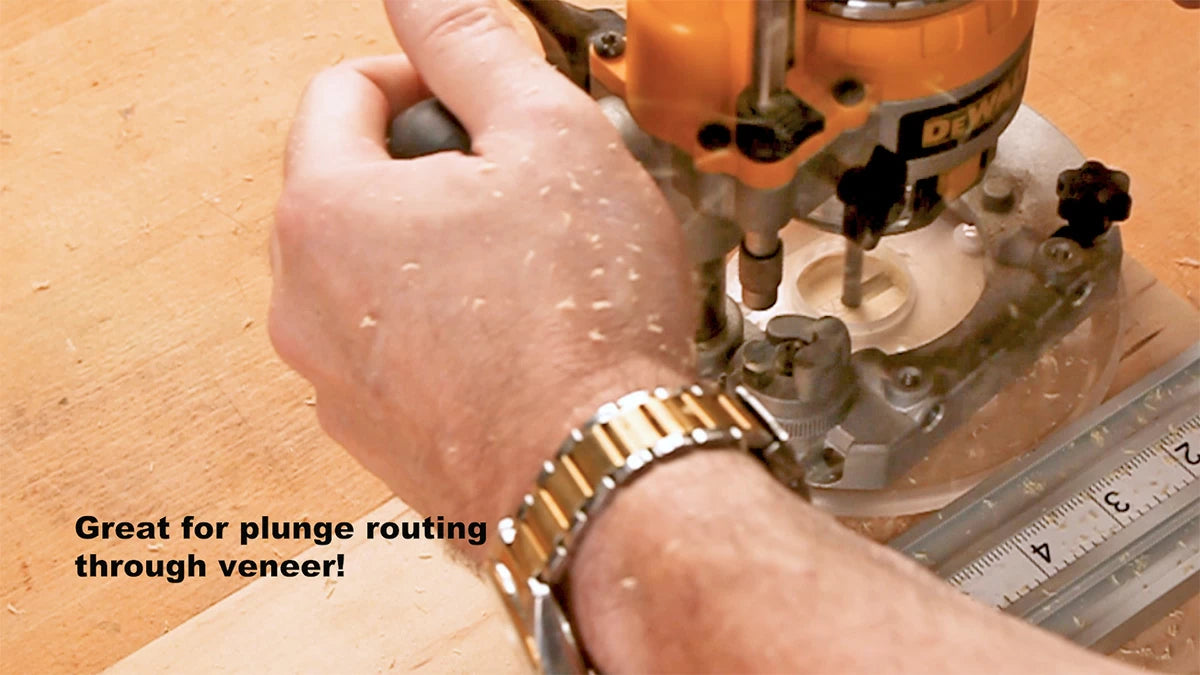

Our Solid Carbide Spiral Compression Router Bits aren't only for edges. They'll do a great job protecting veneered surfaces in plunge cuts and many other applications.