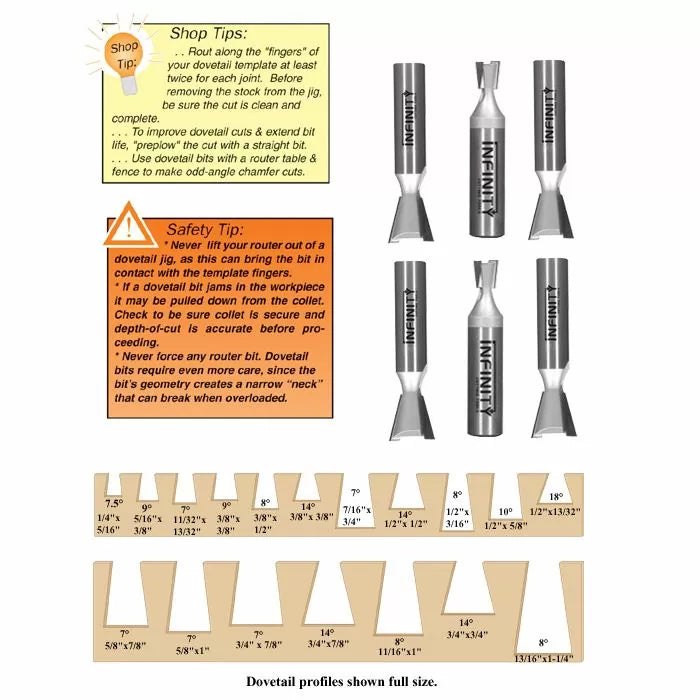

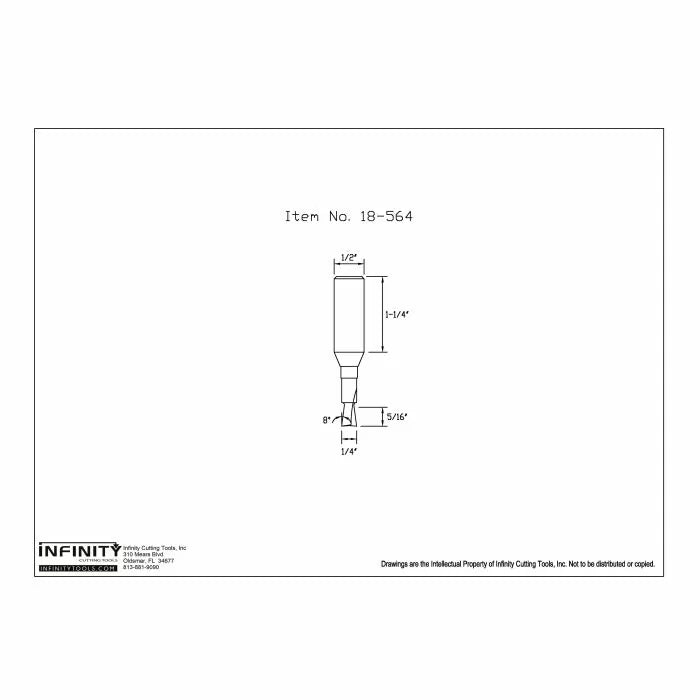

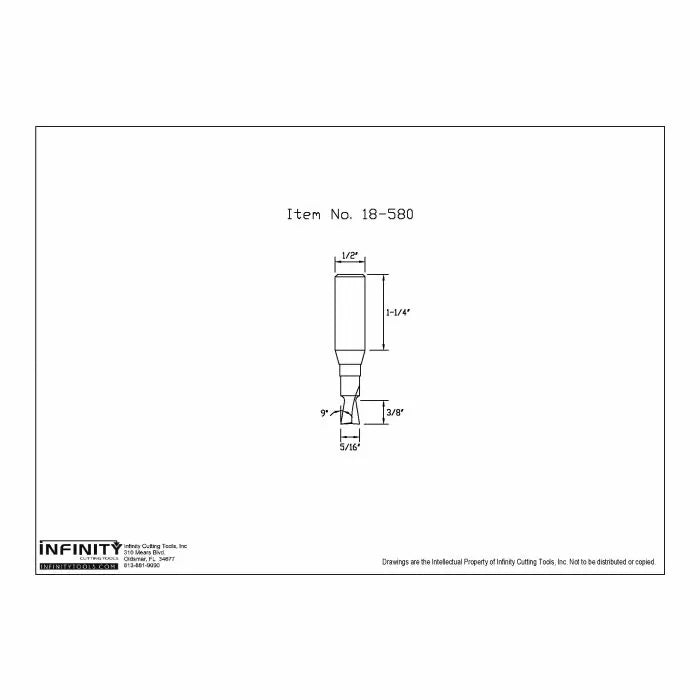

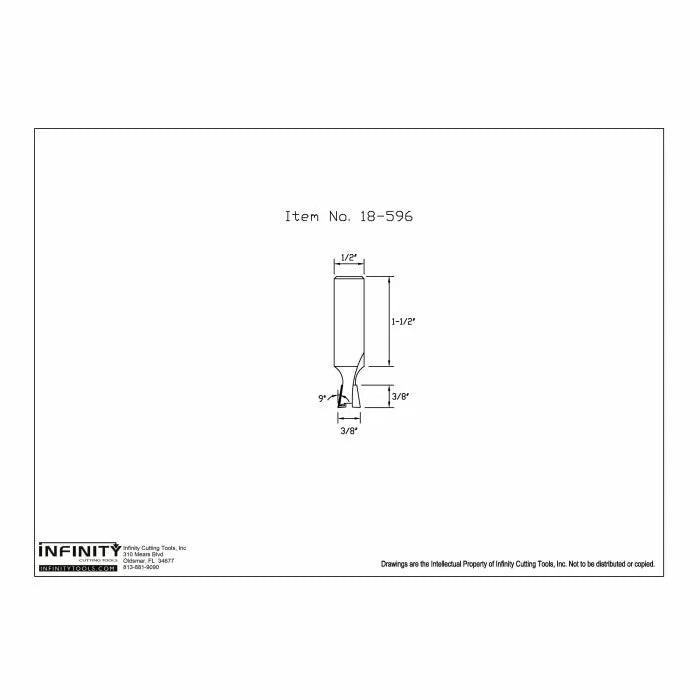

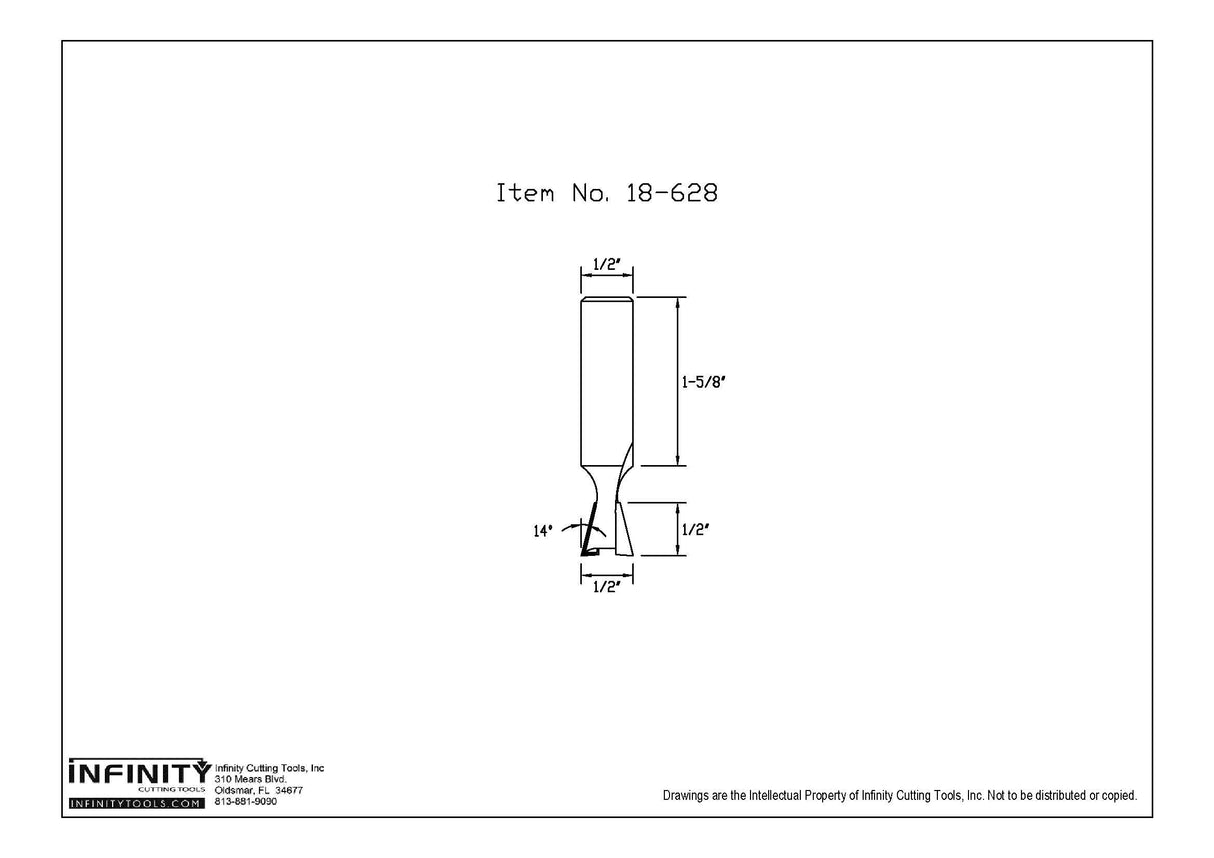

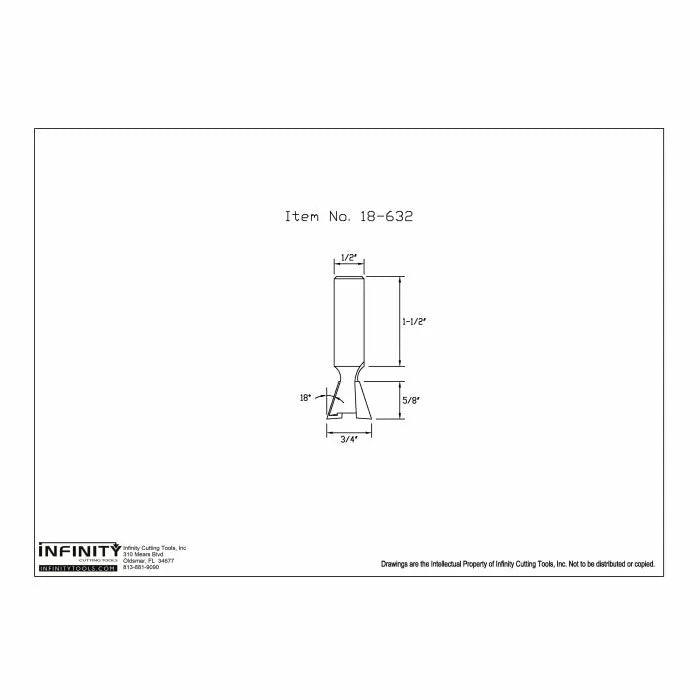

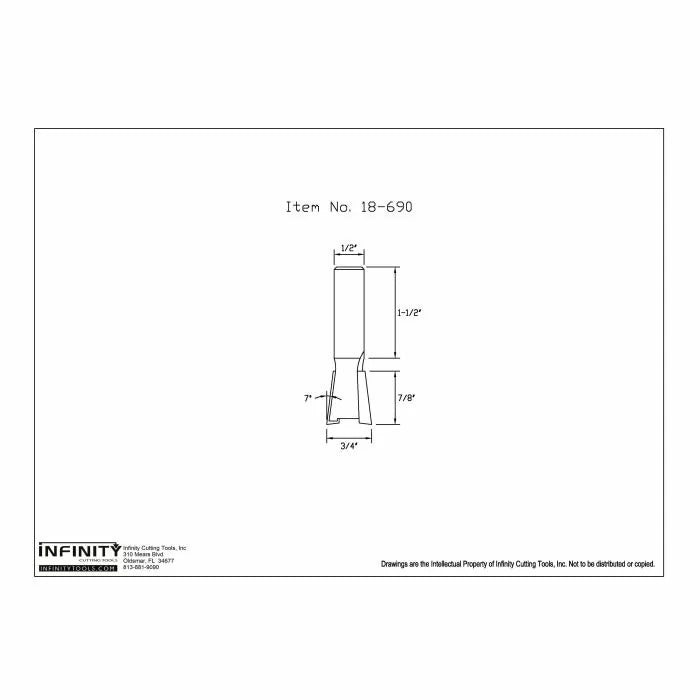

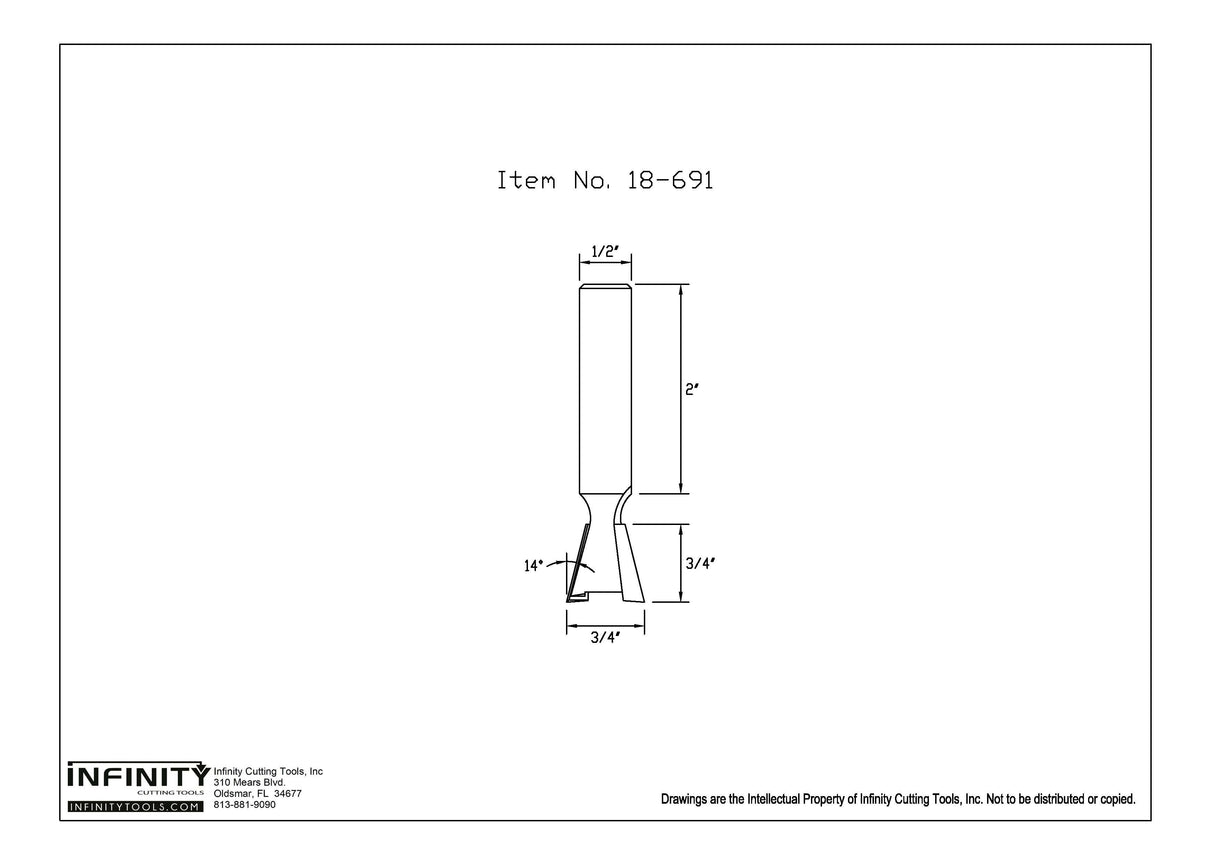

With 12 of the most popular 1/2" shank Dovetail Router Bits too choose from, we're sure to have the perfect dovetail router bit for your next project. Because of their 'neck' geometry, properly made dovetail router bits are tricky to produce. Our dovetail router bits have been specially designed on advanced CAD software to provide the smoothest cuts possible and work with the most popular jigs. Use these fine carbide tipped cutters to build drawers, jewelry boxes, humidors, Shaker style furniture, shadow boxes and much more. We also offer complete, money-saving sets for the Incra, Leigh, JoinTECH and Omnijig systems. Made with exact shear angles and premium grade materials our bits will make your next dovetail project a smashing success.

Pro tip: always pre-plow your dovetail grooves with a straight router bit to remove the majority of your material before running your dovetail bit profile. This will greatly extend the life of your dovetail router and improve the quality of cut. Choose a straight router bit that is the the same or slightly smaller than the smallest diameter of the dovetail bit.

Whether used in contemporary, or classic furniture, dovetail joinery is a highlight of quality woodworking.

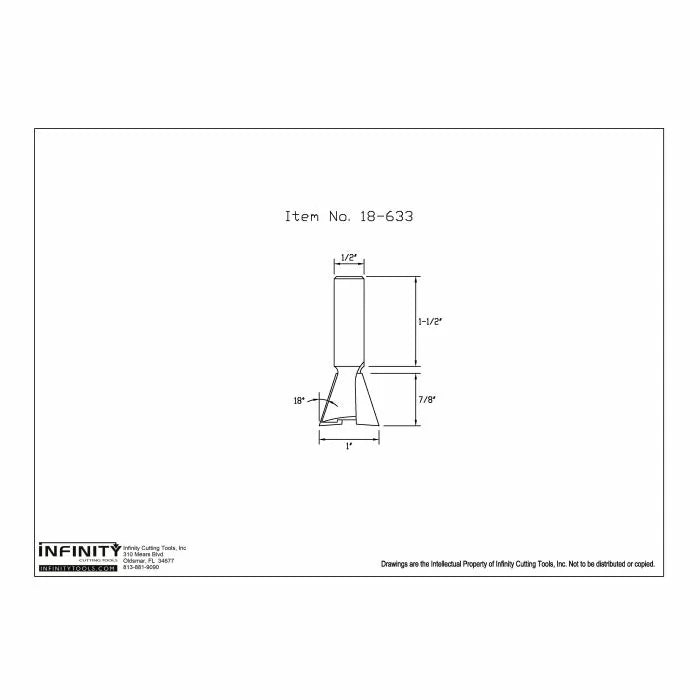

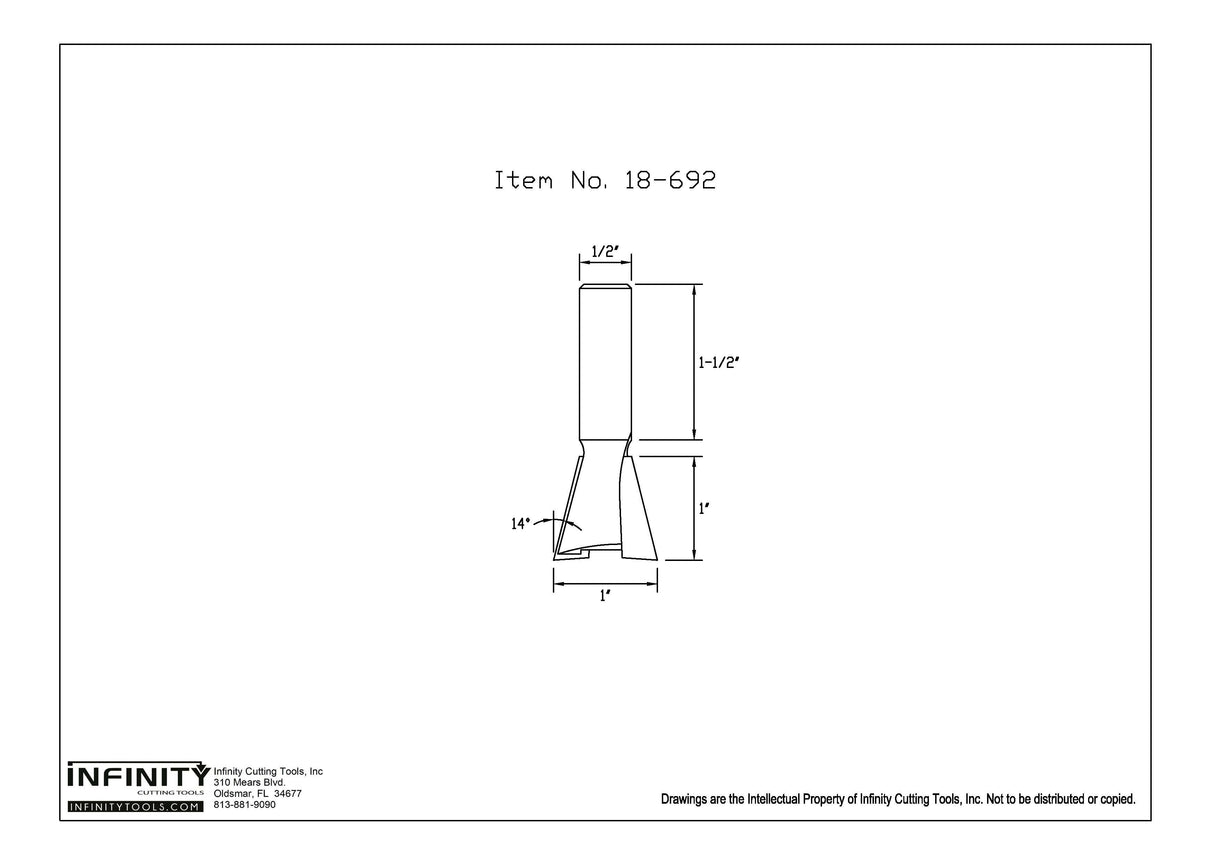

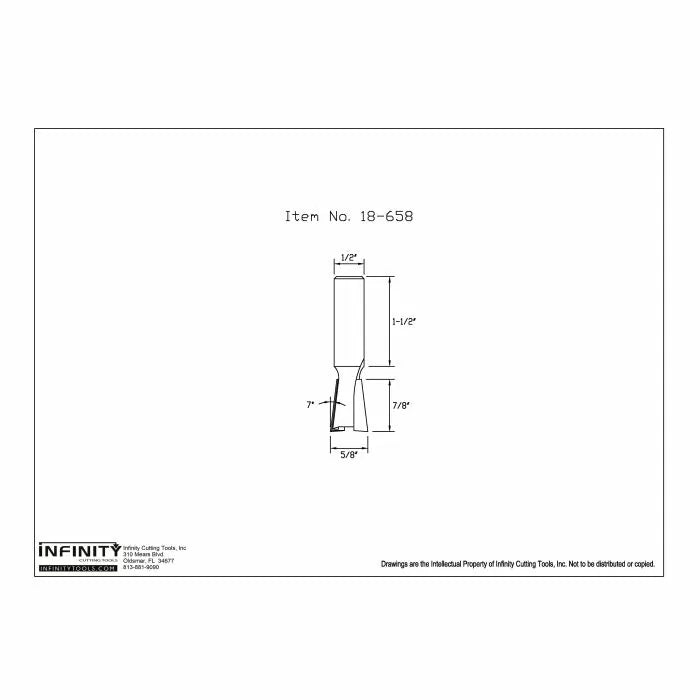

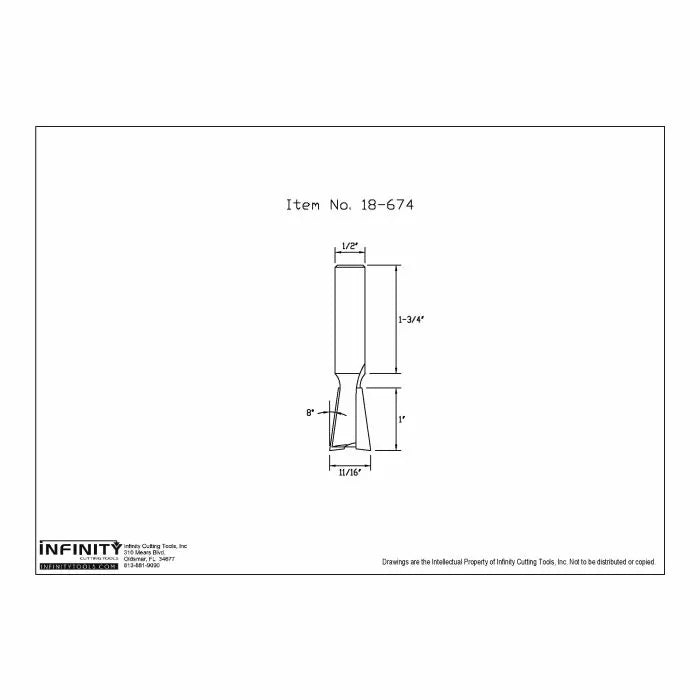

Infinity Tools offers a large selection of dovetail bits designed with negative shear angle to provide ultra smooth cuts, and they’re available in all sizes and for all needs. But one thing that doesn’t change … is the general shape of the bit. The weakest point of all dovetail router bits is their neck. To get the longest life possible from this type of bit, we recommend pre-plowing the groove before cutting the dovetail slot.

Pre-plowing is the concept of using a straight bit (sized smaller than the diameter of the neck) to first cut a clearance channel. Start by finding the diameter of the neck of the dovetail bit using a caliper.

Then you locate an appropriate straight bit slightly under the diameter of the neck of the dovetail bit. Use that straight bit to set up the plowing cut.

You make a first pass with the straight bit to remove much of the waste. Remember don’t run this straight bit too fast. Let the bit cut.

The dovetail bit is then used to follow through that channel, but the stress on the bit is greatly reduced, leading to better dovetail cuts … and a longer life for your dovetail bits!

Follow this simple tip and you'll get the best performance from your dovetail router bits.