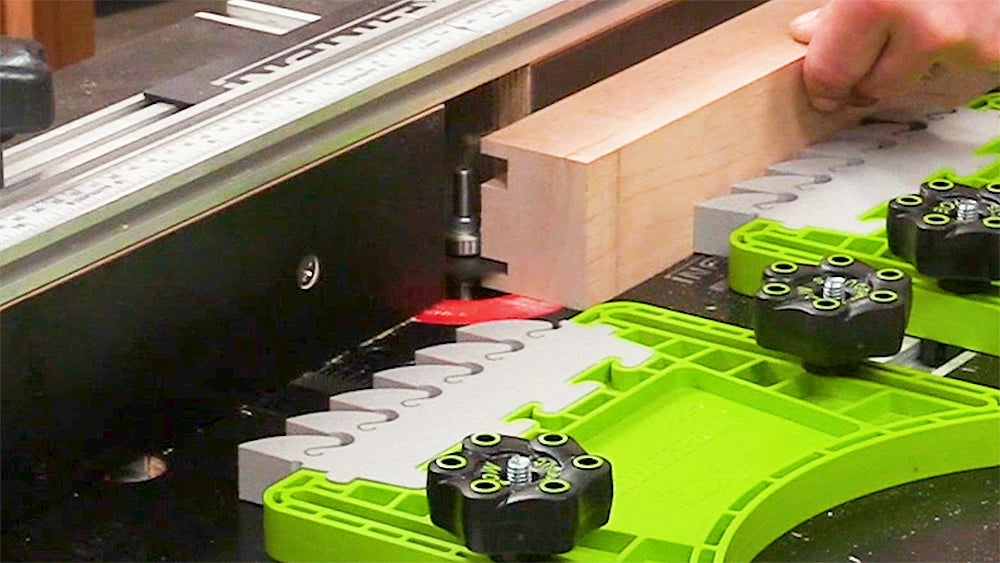

A single pass with a single cutter is usually the most accurate way to a cut a slot, dado, rabbet, or groove of the correct width. Unfortunately, there are many circumstances where you don’t have the right cutter for the job. Your cutter and your stock just don’t match up. Solve this common problem with our Full Stack Slot Cutter Router Bit kit.

Actual thickness of plywood and dimensional lumber is almost always smaller than the nominal width. Unfortunately, most router bits tend to match up with these nominal widths. Even if you have specialized bits for undersized plywood, you can’t count that each sheet of plywood is uniformly undersized either.

Plywood and dimensioned stock are the most notorious culprits, but even lumber you mill is susceptible to miscalculation. It’s easy to plane stock to the width of the cutter you plan to use to make slots and grooves, only to unintentionally shave a little bit too much off, or realize too late that your planer’s gauge was improperly calibrated. Normally, you’ve three options: 1) new lumber; 2) risk another mistake by using a smaller bit to make multiple passes; or 3) acceptance of a loose joint.

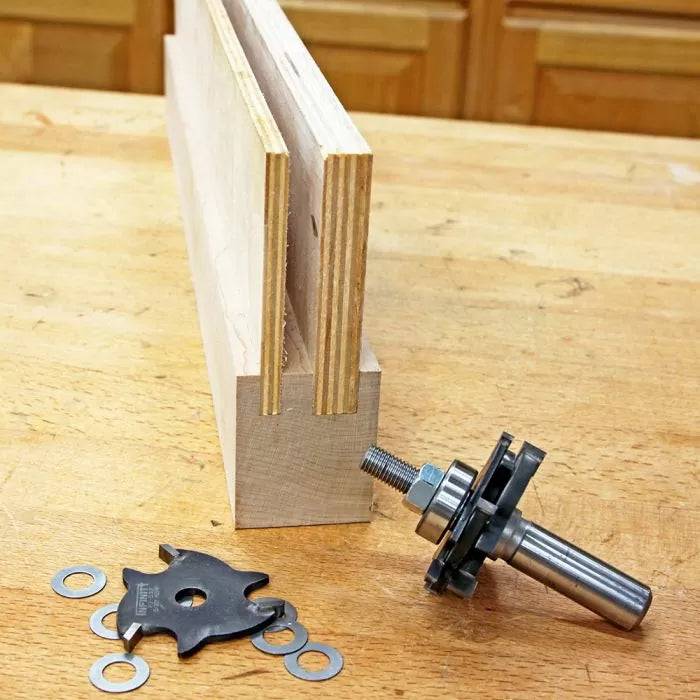

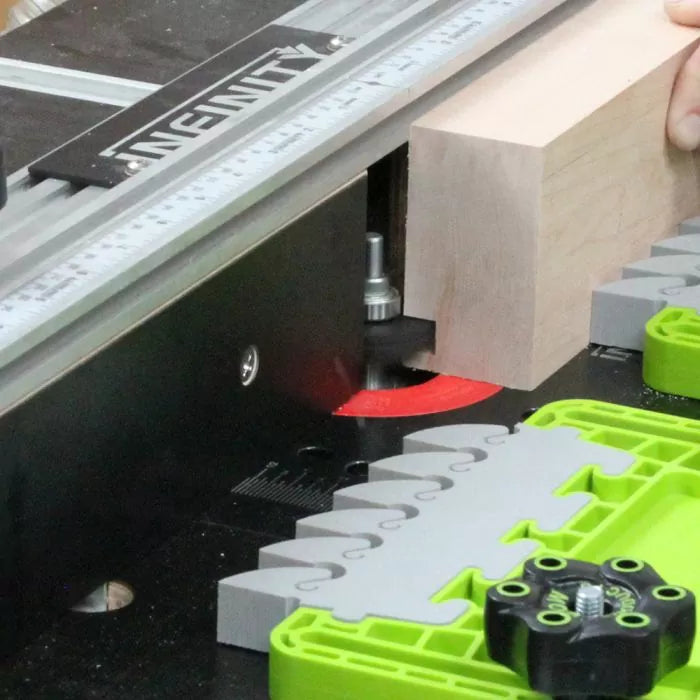

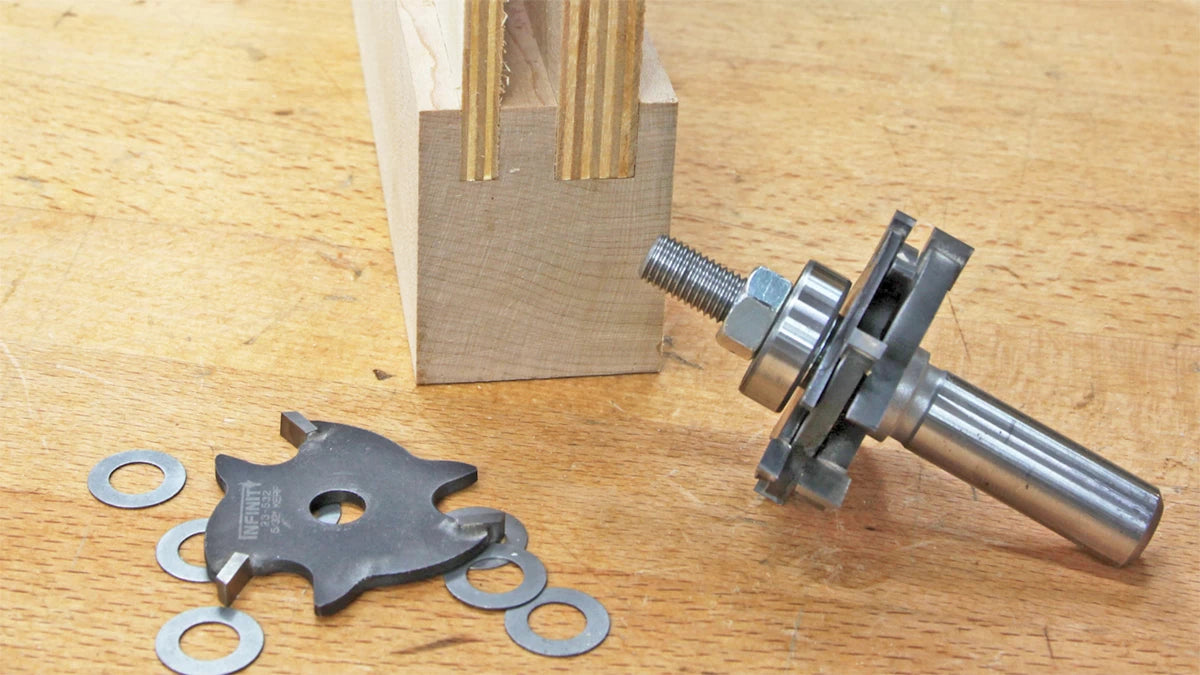

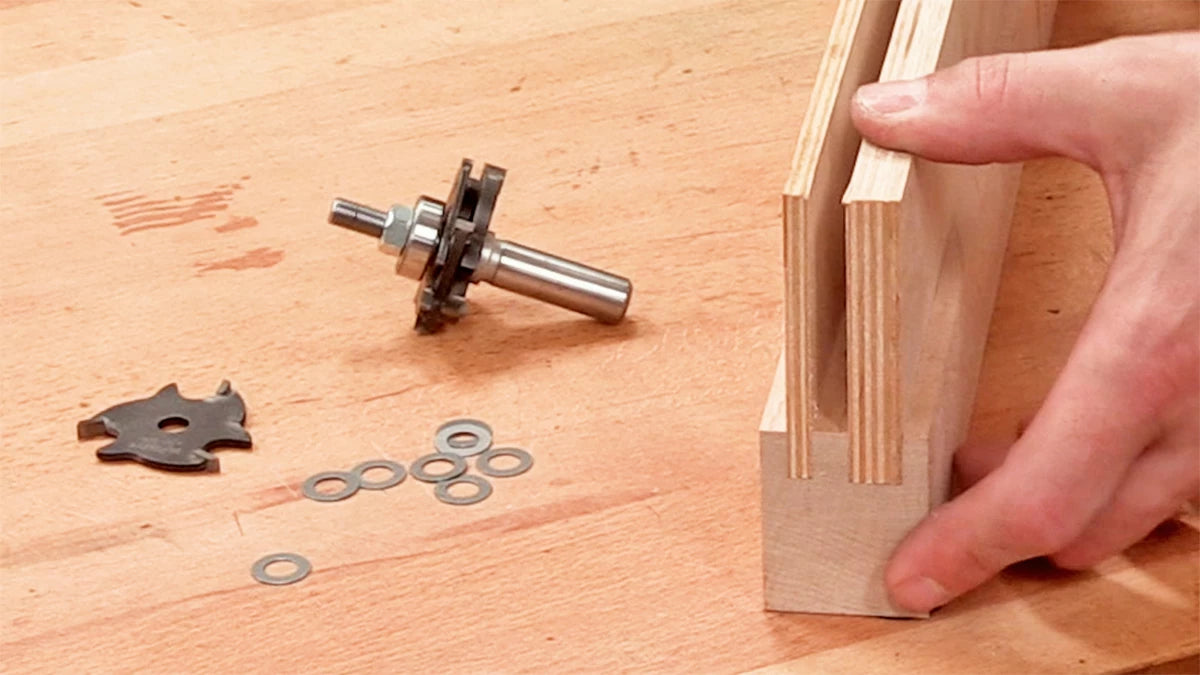

Don’t worry about making a mistake while sneaking up on cut width with an undersized bit, or settling for a sloppy fit with a slightly oversized cutter. Anywhere from 1/8” to 11/16” cuts are possible with this supremely useful bit set.

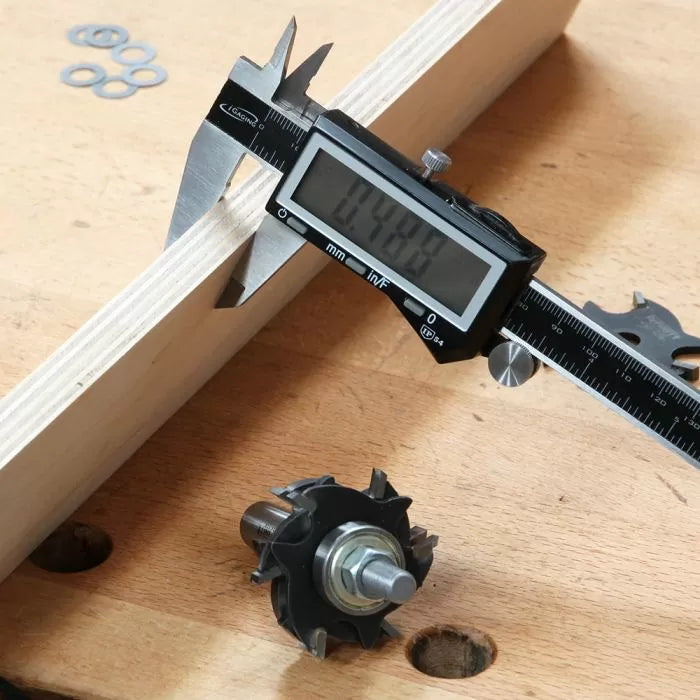

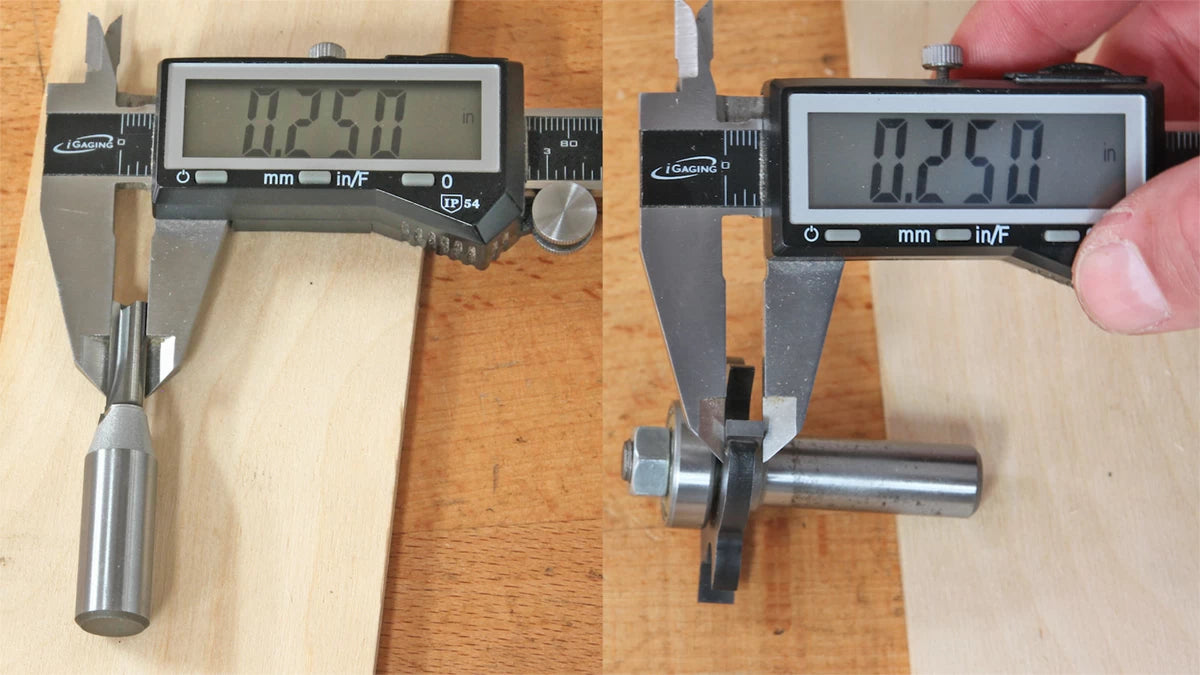

It’s as simple as measuring the thickness of your stock, and then stacking the cutters and shims until the cutter height matches the stock thickness. Our Full Stack Slot Cutter kit comes with four cutters sized 1/4”, 3/16”, 5/32”, and 1/8”; a 1/2” arbor; eleven, .014” shims; and a 7/8” bearing to regulate cut depth. Additional bearings are available separately for different depth limitations.

You’ll be amazed at how tightly you can dial in tailor-made grooves and slots on your next project with this slot cutter combo, and it may just save you from the heartache caused by wasted wood.

You likely know that the actual thickness of plywood is less than its nominal width. Through experience, you’ve likely also learned that even amongst sheets of the same nominal width, the extent to which they’re undersized can still vary.

Even if you’re not using plywood, though, we’ve all had the situation where we milled our solid wood stock just slightly thinner than desired. Maybe the planer gauge was off, or you miscalculated or misread a measurement. Maybe there were undetected defects in the stock that required further milling below the required thickness. Maybe you shave a bit too much off of that tenon or tongue. Just because you no longer have a router bit of the exact thickness needed, doesn’t mean you have to spend a bunch of time dialing in multiple cuts using a smaller bit, or worse settle for a sloppy fit.

Suffice to say, for the best fit, measure the finished thickness of stock that must fit the slot at finished and dial in your cutter for precise, repeatable slots. Never have an ill-fitting joint with plywood or wood you've machined yourself. Stack you way to perfection with the Full Stack Slot Cutter Router Bit kit.