Rasps are a very useful tool for all different types of woodworking. They allow you to shape and refine flat, concave and convex curves. Rasps have been used for centuries to shape things like cabriole legs, table aprons, and any other shaped or sculpted detail found on a piece of furniture. Rasps are also favorites of carvers and luthiers and are used to shape everything from architectural carvings to guitar necks. But not all rasps are created equal, continue reading to find out what makes these hand-stitched rasps a cut above.

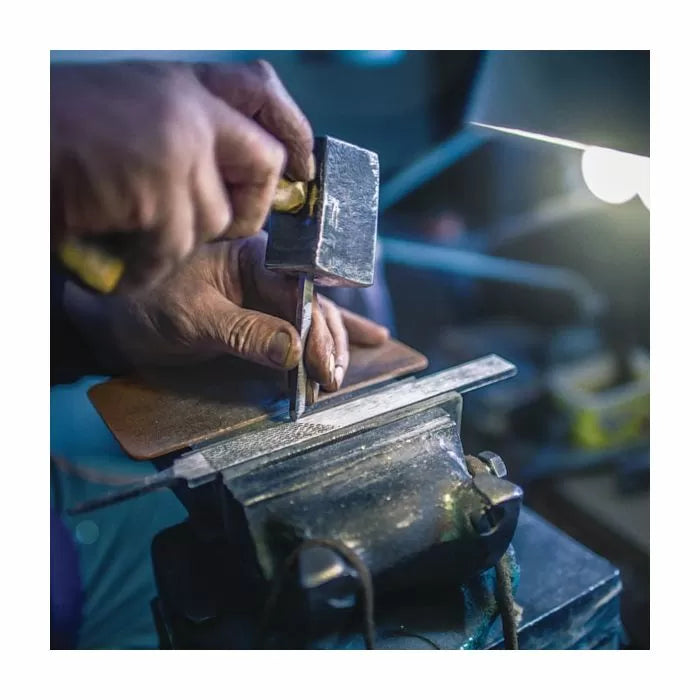

Narex Hand Stitched Cabinet Makers Rasps stand out because of their high quality and old-world manufacturing techniques. Rather than having the teeth punched out symmetrically by a machine, hand-stitched teeth are made one at a time by a craftsman using a hammer and special chisel. This process creates a rasp with a slightly random tooth size and pattern. This irregularity allows the rasp to cut quickly and still leave an exceptionally smooth surface. Hand stitching also allows the teeth to extend all the way to the very edge of the rasp body for better control and more effective shaping.

All three of the Narex Cabinet Makers Rasps have a 16" overall length with a 10" long body that is flat on one side and has a compound radius on the other. This radius is 1" over the first 6" of the rasp and tapers to a 1/2" radius at the tip. The body is 1-1/8" wide and tapers down to 5/8" wide at the tip. All 3 feature a comfortable and long-wearing hornbeam wood handle.

Available in three grits (or grain patterns as they are sometimes called), the coarse rasp (101-725) has roughly 10 teeth per square centimeter, the medium rasp (101-726) has roughly 30 teeth per square centimeter, and the fine rasp (101-727) has roughly 60 teeth per square centimeter. All three are available individually, or you can purchase the three-piece set (00-724) and save a few bucks.

In use, these rasps remove material with exceptional speed while leaving a surprisingly smooth surface. We used each rasp to shape and refine a curved surface on a piece of Sapele in order to get an idea of the scratch pattern each of these rasps leaves on a workpiece. Be sure to take a look at each of the photos below for the results.

As expected, the Coarse rasp cut very quickly, hogging off a lot of material in a hurry. Despite having large, aggressive teeth, you can see that the surface left behind is reasonably smooth, especially for how aggressively it cuts.

In my opinion, the medium rasp is the real sweet spot in this set. It cuts reasonably fast for most furniture projects and leaves a fairly easy-to-clean scratch pattern.

The Fine rasp leaves an exceptionally smooth surface and is great for removing the scratch pattern left by the Coarse or Medium rasps before a final sanding or scraping. If you work with exceptionally hard woods like white oak or any form of exotics from Africa or South America the fine rasp is a must.

The bodies of these rasps are made of carbon steel and require some maintenance to prevent oxidation. After each use we recommend cleaning the sawdust from the rasp using a stiff nylon or brass bristle brush then apply a light coat of oil as you would any other quality tool.

Sized with the cabinetmaker in mind, with grit ranges to suit most any species and method of work, the Narex Hand Stitched Cabinet Makers Rasps are an exceptional value. Designed and executed with the professional and serious hobbyist woodworker in mind, they will certainly be a workhorse in your shop for years to come.