Frame-Making Router Bits

Making beautiful picture and mirror frames is easy with this select collection of Infinity Cutting Tools router bits. These bits work perfectly to make any component of your picture or mirror frame. These premium quality cutters can also put decorative edges on fire place mantels, chair rail molding, or even use multiple bits for an extra tall custom crown molding project. Make sure to choose the 6-Pc. Master Frame Making Set and get all of the router bits you'll need to make your next custom frame project a success!

Any project that requires accurate miter joints can be intimidating, but a one-of-a-kind picture frame can be well worth the effort. Let me take you step-by-step through my process for designing and building picture frames. In this blog, I will show you how to get tight, well-fit miter joints, and how to create unique frame profiles by combining different router bits.

When it comes to designing a frame there are a lot of options, so lets start with the most important part — the back-side rabbet.

This is usually the last step I do before cutting my miter joints, but it is worth thinking about early on. What is it that we're framing? How thick are all the parts that the frame needs to hold? Will it include glass or a backer? If we know at the start how thick the stuff inside is going to be, then we can gain an idea of how thick the wooden frame needs to be to hold it all.

After we figure out the function, we can decide how the frame is going to look. The sky's the limit, here. In our shop at Infinity Tools, we've put together a few great sets of router bits that are perfectly suited for making a wide range of frame designs. To make your design decisions easy, here are five of my favorite picture frame profiles that can all be made with the Infinity Tools Master Frame Making Router Bit Package (item 00-516).

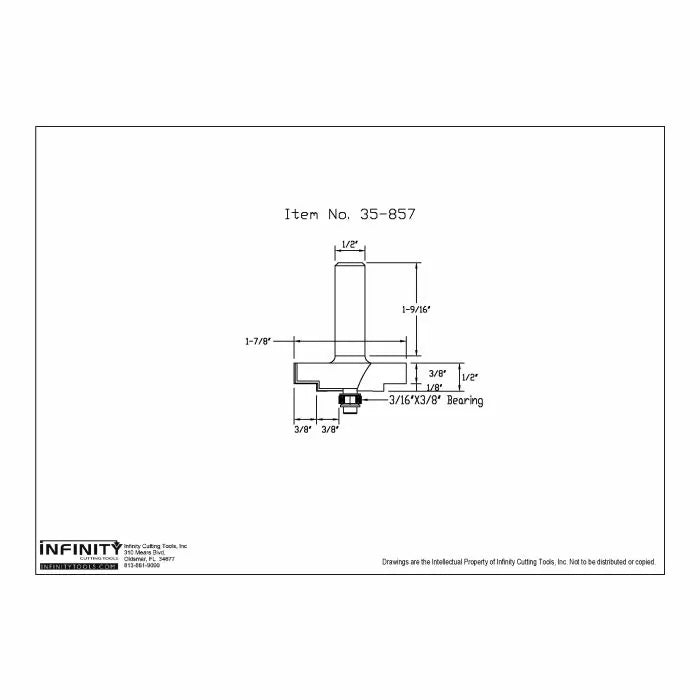

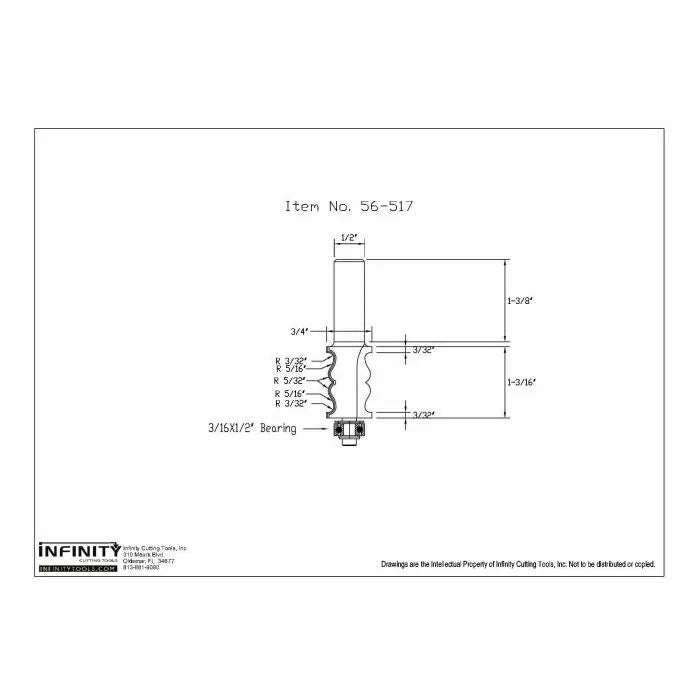

The first frame can be made with a single Picture and Mirror Frame Making Router Bit (item 56-517). In a single pass, you can produce the profile and then run over the back with the Stepped Rabbet Router Bit (item 35-857) to create the rabbet on the back.

I like to use the Infinity Tools Stepped Rabbet Router Bit for picture frames because it produces two steps. The first step is 1/8" deep by 3/8" wide so it's sized just right to hold a 1/8" thick pane of glass. The second step is an 3/8" wide, and will the subject of your frame inside nicely. The great thing about this arrangement is that you're less likely to damage the glass when securing the picture in place.

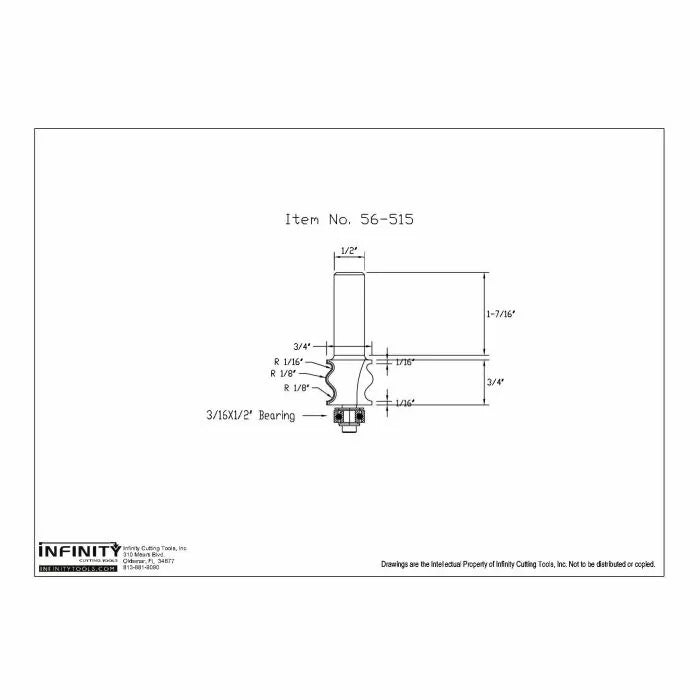

The next frame uses a single 56-515 Picture and Mirror Frame Router Bit, but requires 2 passes. To make this frame I set the bit height, make my first pass, then flip the workpiece over and make the second pass (see image below). The key with this frame is to make sure the frame width is double the height of the router bit minus any part of the router bit profile you want to overlap.

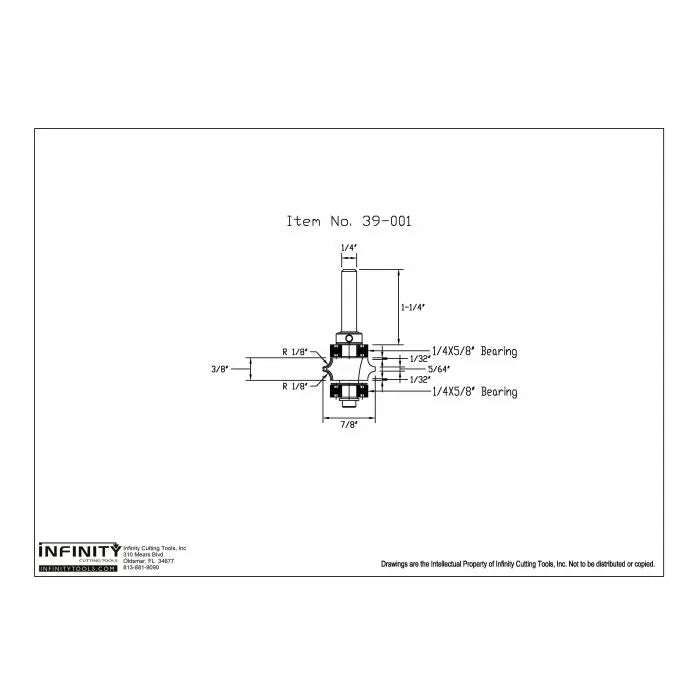

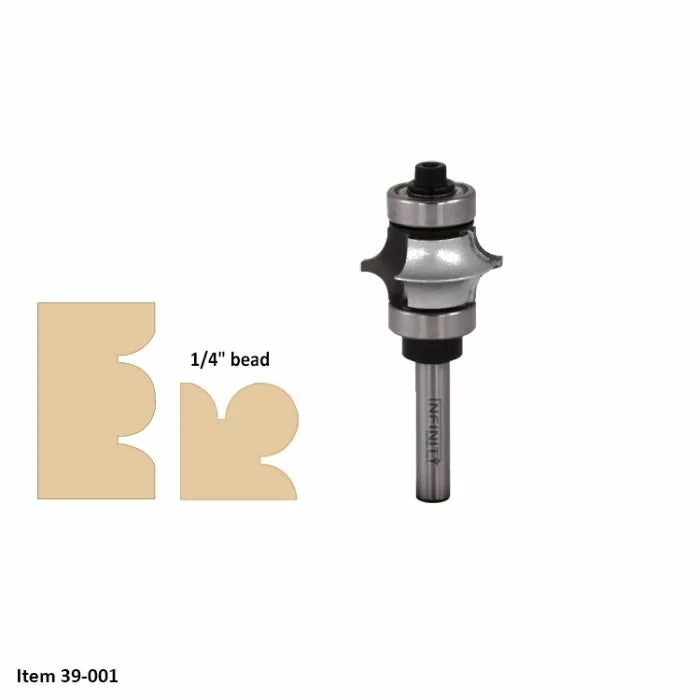

The third frame uses the same 56-515 Picture and Mirror Frame Router Bit, but we'll add an extra element. Here you'll still make two passes over the router bit, but you'll also create a bead between the two profiles with the Infinity Tools' Full Bead router bit (item 39-001). This creates a stately little bead down the center of the frame, adding interest to the piece without adding much complexity to your setup.

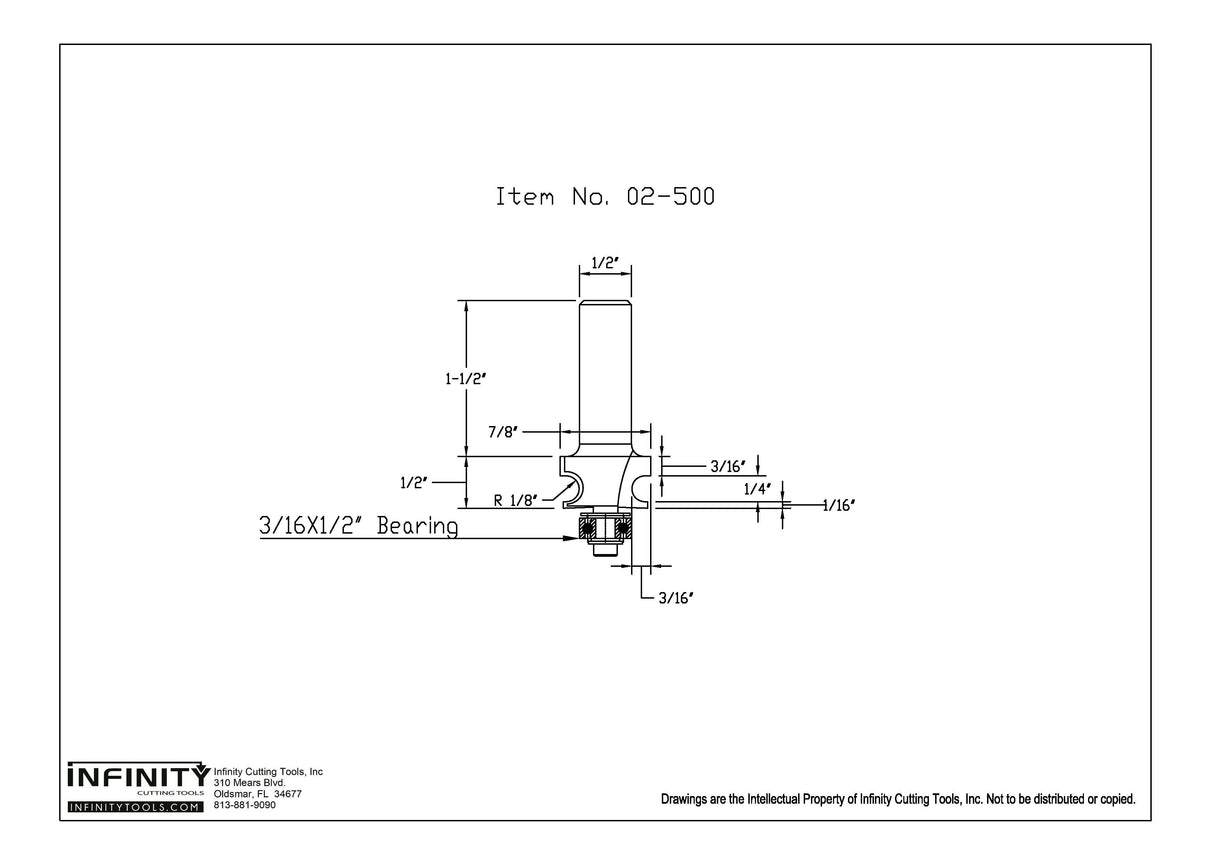

The next frame is fairly simple requiring a single pass through a 56-516 router bit and a single pass through an 02-500 edge beading bit. It's great for wider frames because the flat portion in the center of the bit can be adjusted to suit your taste. My frame has a 5/8" flat portion in the middle.

The final frame is the most complex, but it's actually fairly easy to make. Start with the same router bits and process as above, then, using the 56-515 Picture and Mirror Frame Router Bit profile, you'll cut a separate strip that will be inlaid into a groove in the face of the frame. The 56-515 router bit fits for the inlay strip because it has 5/8" wide profile that will fit snugly into the groove we'll make down the face of the wood.

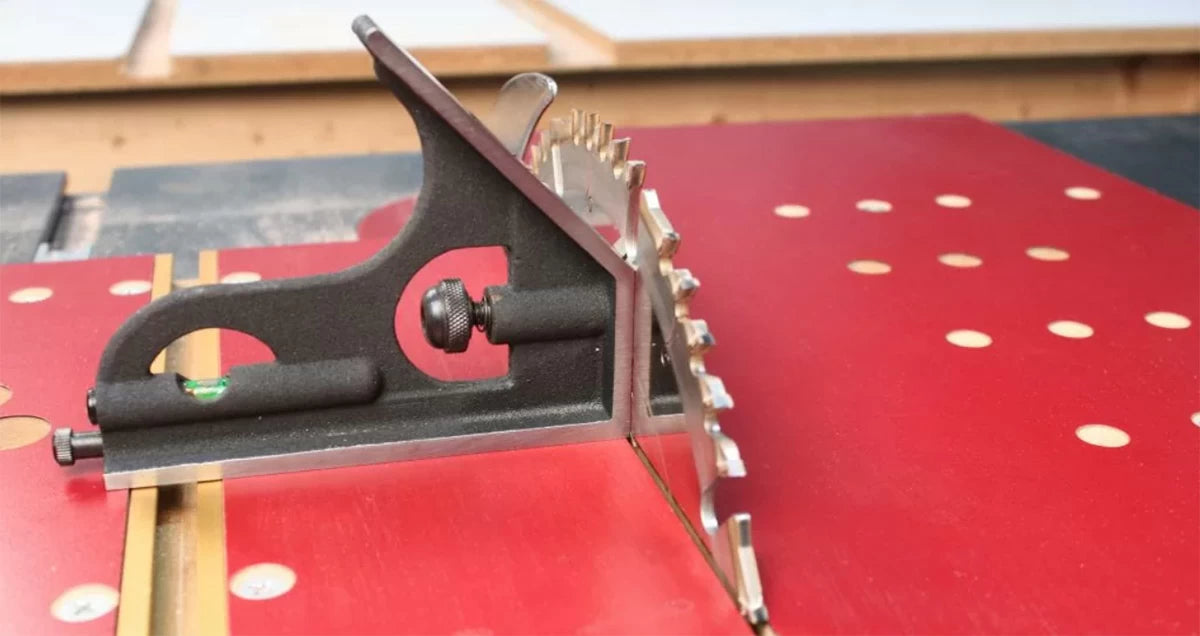

Once the faces of my frame are made, I head over to the table saw and cut a 5/8" wide dado for the strip to fit into. Once again, my Infinity Tools Dadonator 8" Stacked Dado Saw Blade Set (item SDB-800) has a chance to shine!

Once the faces of my frame are made, I head over to the table saw and cut a 5/8" wide dado for the strip to fit into. Once again, my Infinity Tools Dadonator 8" Stacked Dado Saw Blade Set (item SDB-800) has a chance to shine!

If you want the inlay strip to really pop, try using a contrasting species of wood. With the right color combination, you could just leave the inlay square and drop it straight into the dado. This is a really handy trick when you want a really wide frame.

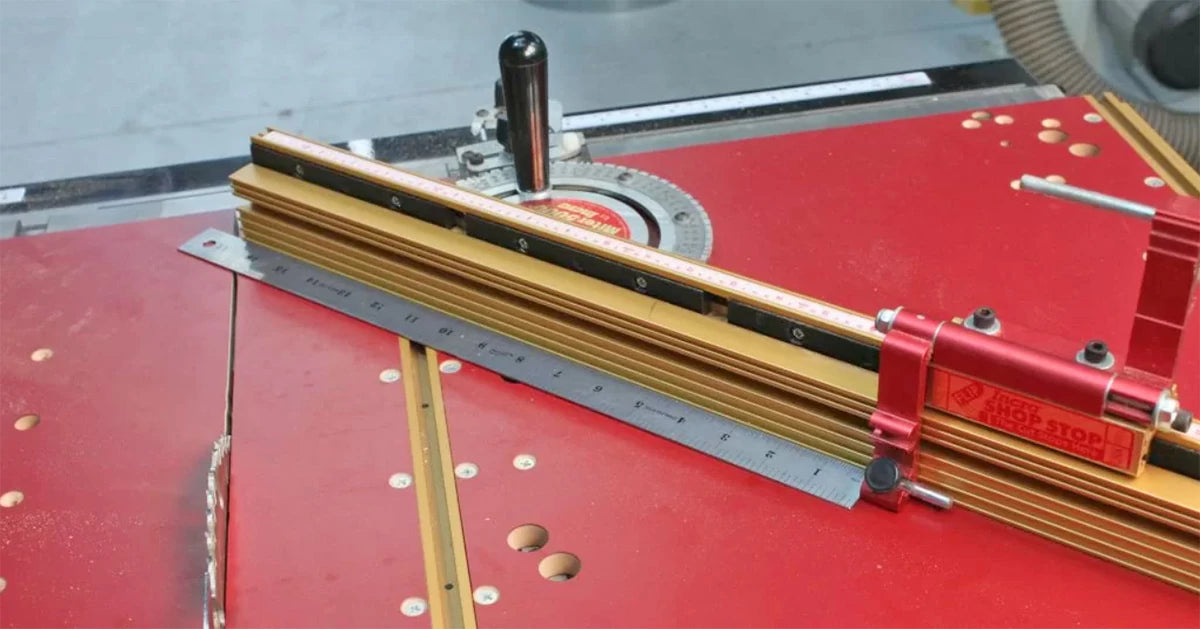

Regardless of how good your frame stock looks, if your miters don't fit together the frame will not look professionally made. For picture frame miters I actually pass on the miter saw and head over to the table saw. There I'll either use a quality miter gauge an adjustable crosscut sled. The Incra Miter 5000 Table Saw Crosscut Sled (item IMG-005) is my first choice for making this kind of precise cut because it allows me to get a very accurate miter and set up stopping blocks for repeatability in my cuts.

Referencing your cuts off of your sled's stops is important. You can make perfect 45° cuts all day long, but if your right and left pieces are not exactly the same length your miters will not fit together perfectly. The same goes for the top and bottom. Whether you use the Incra Miter 5000 or a homemade sled, take the time to dial in your stopping blocks. I use the head of my 6"Combination Square (item 100-124) to ensure my sled is set to a perfect 45°. It's also handy for double-checking that my miter fence is square to the table.

I used a few pieces of painter's tape to shim my fence to the stand at a true 90° angle to the table. I also manually set my fence to 45° to the blade to ensure a perfect corner. To round it off, I also double-check that the blade is set at 90° (better safe than sorry).

When I go to cut my pieces I make one cut, then flip the workpiece over and slide it against the stop and cut the other end. Then I cut the corresponding piece in the exact same manor. The Flip-up stop on the Incra Miter 5000 Table Saw Crosscut Sled makes this so easy you don't even have to think about it.

If I am making multiple frames of the same size I cut all the pieces to the same length, then I reset my stop and cut the rest. This ensures that all my pieces are exactly the same length, which -not coincidentally - also ensures that all of my frames will be square when joined together.

It is never a bad idea to make a few test cuts before cutting your frame stock to length. Putting two 45° pieces together and checking them for squareness will double any angle errors present, which means you will be better able to notice any flaws before your final glue-up.

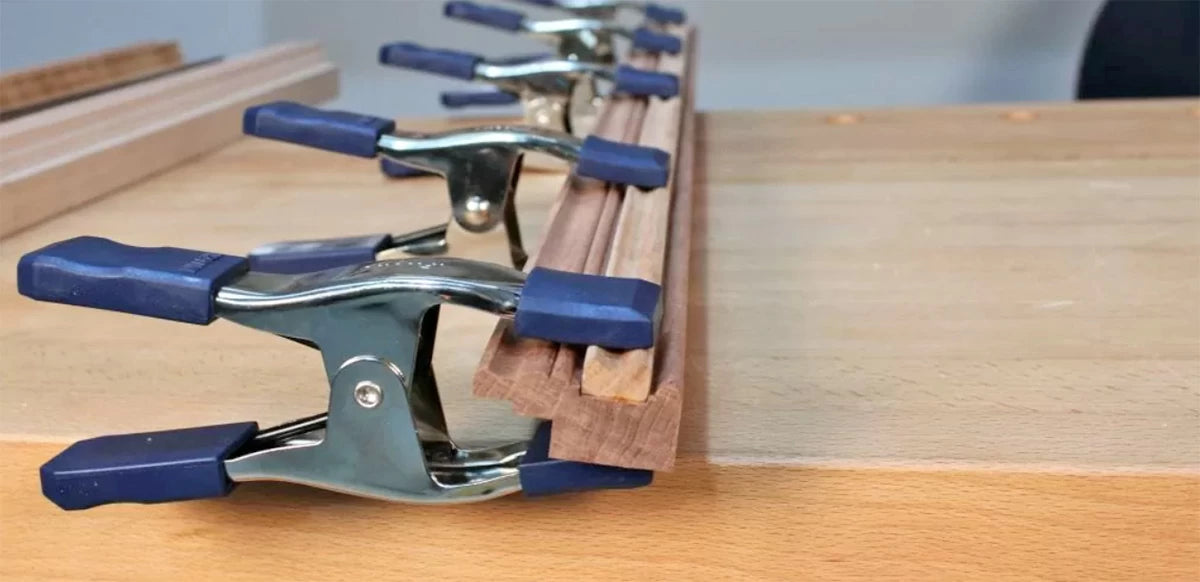

With all pieces cut, its time to assemble. There are a lot of corner and frame clamps on the market, but I like a clamp that secures the entire frame at once and gives me room to pin the corners with a brad nailer. An Adjustable Four Corner Frame Clamp (item 100-595) works like a dream because I can make sure all four corners of the frame are just right before gluing and pinning.

The nice thing about this method is a lot of clamps can be assembled in a hurry. Once the frame is glued and pinned it can then be removed from the clamp, freeing it up for the next frame you want to assemble. There are few things in life I hate more than tying up my clamps just because I'm waiting for glue to dry.

The final step is to grab a damp rag and wipe away the excess glue. This is a step you do not want to skip because it is a real pain to try and sand away dried glue in all of the tight corners of a picture frame. Once the glue is dry you just need to apply your favorite non-toxic wood finish, install your glass, and some artwork to your newly assemble work of art.

1 comment

Product looks good. I’m not buying US products. Good luck.