You know there's a correct way to install woodscrews, right? When joining two pieces of wood, a shank hole should be drilled through the workpiece you're attaching to another piece. This hole is sized so that the screw threads pass through without grabbing. This prevents the workpiece from "jacking up" when driving the screw. You know what I mean — you've had it happen. And when this happens, there's often a gap between the workpieces no matter how tight you drive the screw.

But it's the pilot hole that also must be properly sized. This is where the screw threads actually engage the wood to draw the pieces tight. And it makes a difference whether it's hardwood or softwood. Screw threads will "bite" better in hardwood, so the pilot hole can be slightly larger than it would be in softwood. A pilot hole that is undersized can risk breaking the screw as it's driven in. (Here's a link to a handy chart for all the proper drill sizes for woodscrews.)

And let's talk about installing flathead woodscrews. They should be countersunk flush or below the surface of the wood. So this adds a third dimension to the screw hole.

My past experience has been to hunt around and visually compare a drill bit to the actual screw I'm using and say to myself, "That's close enough." Then there's the issue of drilling the pilot hole, switching bits to drill the shank hole, then finishing up with a countersink or counterbore. The all-in-one countersink/drill bits were a godsend when they came around. But too many of us assume that drilling the same size hole for the shank and threads is "good enough." (See my earlier comment about "jacking.")

Did I also mention that after drilling, you need to switch bits to drive the screws?

Fortunately, there's an easy solution that addresses all of the frustrations when drilling and driving wood screws. It's the Snappy 25-Piece Countersink & Quick Change Drill Set by Infinity Tools. It may look like your average, run-of-the-mill drill/driver set, but there are a lot of features that make this set a must-have in your shop.

First, the set includes a quick-change chuck. Simply install it in your drill or driver then changing bits will literally be a snap. The quick-chuck accepts 1/4" hex-shank bits or drivers.

There are drill bits sized for drilling pilot holes for woodscrews. Then you can switch to the countersink bits for drilling the shank clearance hole and countersink in one operation. But there's another benefit to the system — you can set the depth of the countersink or counterbore by using one of the two included stop collars.

And when it's time to drive the screws, you get a set of Phillips and square drive bits to drive the most common woodscrews.

But those aren't the best features, in my opinion. For me, it's the attention to detail that Snappy puts into their tools. They're made in the USA of quality components you won't find in other sets.

Let's take the set screws that hold the collars and depth stops, for example. They're larger and made of a higher-quality steel than you'd find on most sets. This means they grab tighter and won't strip as you tighten them.

The drill bits in the Snappy set are held in place with a collet, much like the one on your router. You'll notice that the shank of the drill bit holder has hex flats on it for use with a wrench to remove and replace the drill bit.

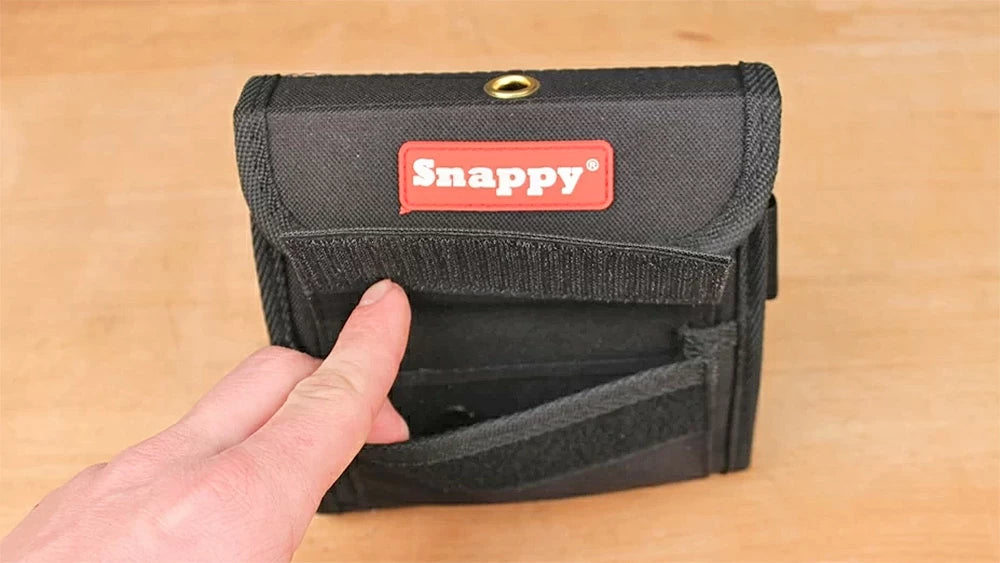

The set comes in a handy case to hold all of the components. On the outside of the case is a handy pocket to keep any extra bits or screws you want to have on hand.

If you want to streamline your time in the shop, invest in the Snappy 25-Piece Countersink & Quick Change Drill Set. You won't be sorry.