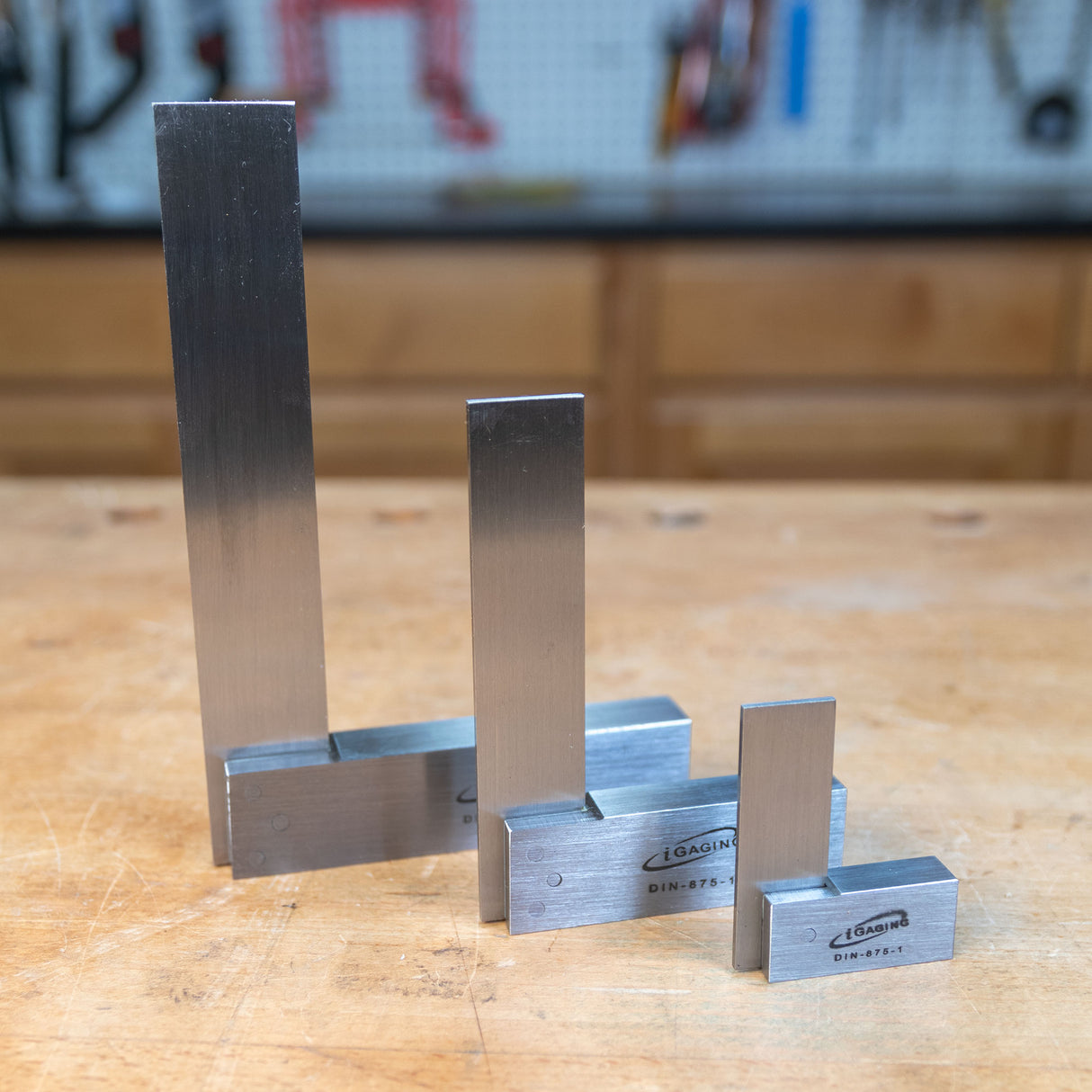

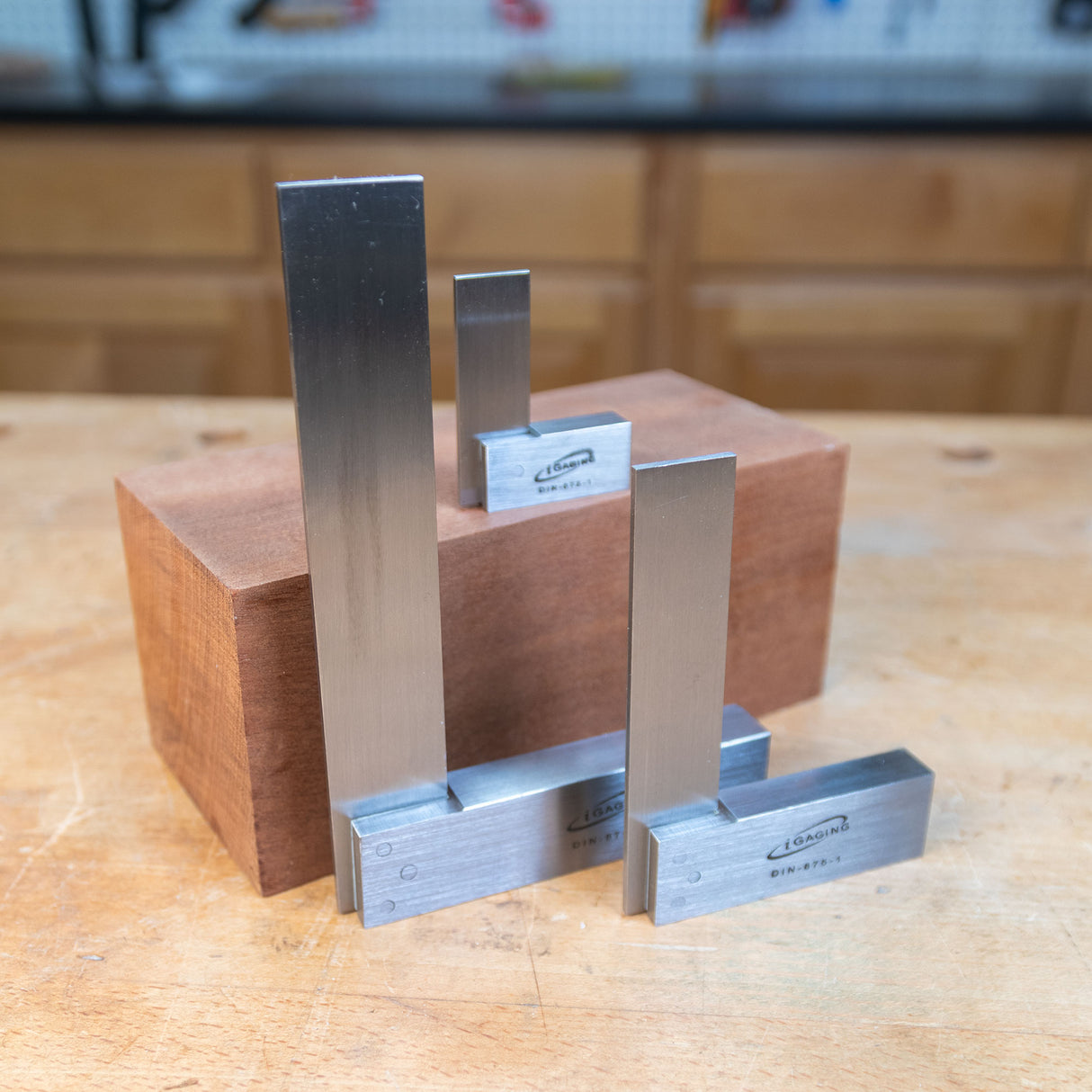

This handy 3-pc. Engineer's Square set is great for machine setup and project layout. They're made from precision ground and hardened carbon tool steel all are guaranteed to be within .001" flat and parallel. You'll use these handy tools to setup your table saw, planer, jointer and many other machines in your shop as well as marking and layout of your woodworking projects. This set makes a great gift for your favorite woodworker and comes with a custom case. Includes a 2", 4" and 6" square, the blades are without graduations.

Use this 3-pc. Machinest square set for:

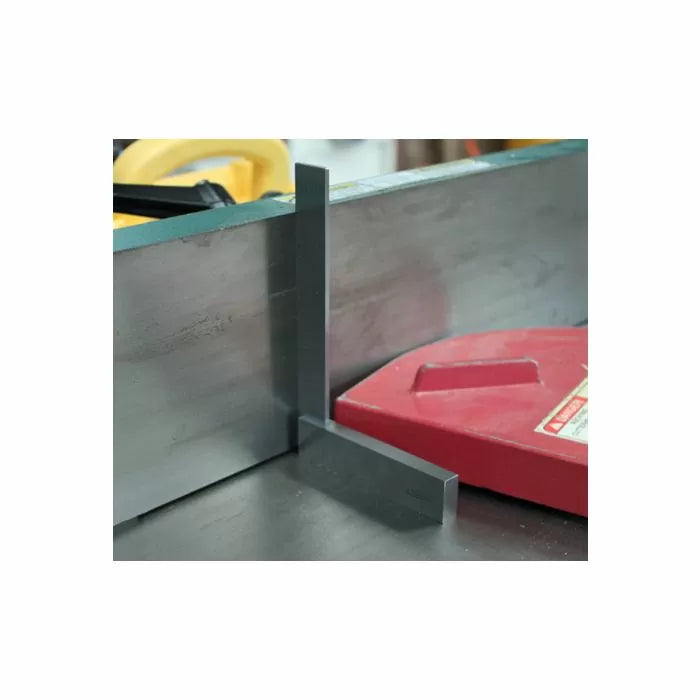

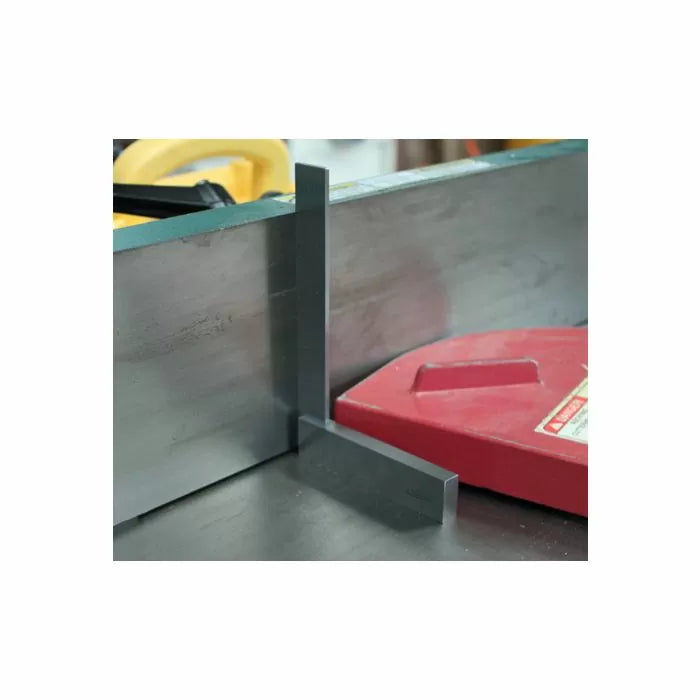

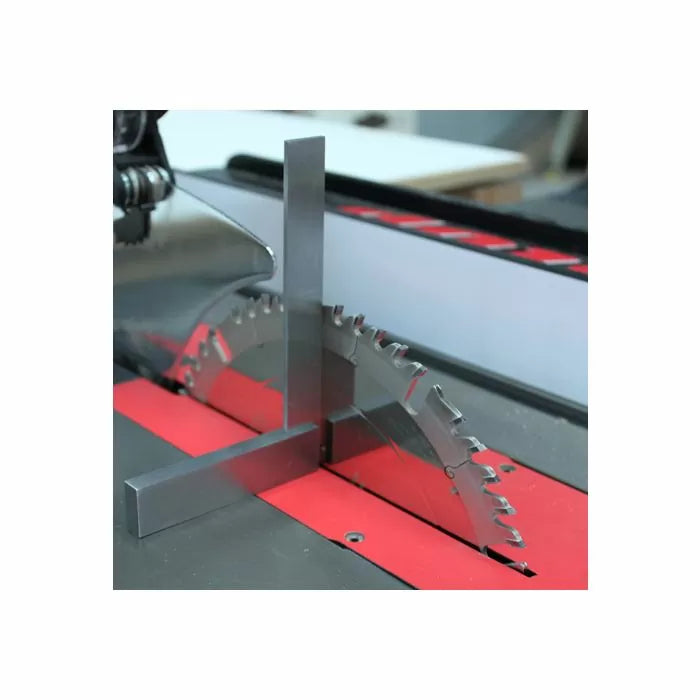

- Setup shop machines like; planer, jointer, tablesaw and bandsaw

- Project layout

- Check project pieces for sqaure

One of the most often asked questions in woodworking circles is “What’s the one tool in the shop that you can not live without?” For me the answer is easy, the 4″ double square. I always have it. I actually have three of them (yes, I know I have a problem), but its really so that whenever I need one I know where I can find one. And I always need one.

Squares are one of the most important tools for me in woodworking. I have multiple ones that all get used. I own a couple 4″ double squares, a 12″ combination square with an extra 24″ rule for it, a couple of precision machinist squares, a carpenter square, and you get my point. Every one of these is useful and needed for me. A majority of other woodworkers use the 6″ combination square as well (but at this stage I’ve admitted I have a problem and just said no, which means at some point I’ll probably buy one). Adjustable squares typically have two parts: The head and the rule. The head will have a knurl on it that you can then use to tighten down where you want your rule to be. The rule will have your measurements on it (either imperial or metric) and up to 4 different graduations.

What, you may ask, will you do with one of these squares? Well…let me kind of put it into a single word. LOTS. You will do lots with your squares. I use one for almost every layout I need to do. Dovetails layout: yup, I grab a square. Mortises and tenons layout: using my squares. Setting the height of a router bit: that’s a task for a square. You get my point. Every shop needs at least one, and you could probably use 10 different types.

Precision squares are great little tools to make sure your equipment and jigs all line up nice and square. Now while a precision square doesn’t have the versatility of an adjustable or combo square, its very tight tolerances and flatness make them perfect for the setting up of your table saw, jointers, fences, and jigs.

The combo square and adjustable square both give you the ability to perform many many tasks, so I’m going to walk you through a few.

The first and most obvious is to be able to check a workpiece for square. You can do this by placing it on a corner or edge and checking to see if any light comes through.

You can find center on a board edge with your combination square. First, draw a line perpendicular to the work face and then draw a 45° diagonal form those two points, where they intersect is your center. Now you can also use the ruler end to slide up to that center mark and have a way of marking center on all of your workpieces that need that layout measurement.

You can tell the true thickness of the workpiece by laying the material flat on a workbench and setting the head of your square on the workpiece and allowing the end of the rule to hit the workbench. This will tell you the thickness of your workpiece and after you tighten the knurl on your square, you can use this measurement to do any of the layout lines you need with that thickness. This can also be done to tell you the depth on a groove or how deep your mortise needs to be, which then allows you to mill up exactly the matching part.

You can set your router height by laying the end of the rule down on the table and raising the router bit up to the square’s head.

Need a line that runs parallel to the edge of your board? Well, that’s not too terribly hard with a square. Place your pencil or marking knife against the end of the rule and let it follow along with your square as you run it along the workpiece.

When choosing tools for your workbench, don't underestimate the humble square. A go-to tool!