10" Multi-Material Saw Blade

Our Multi-Material saw blade features advanced Triple Chip geometry for smooth cuts in "alternative" materials. This is the blade you want for cutting abrasive materials like MDF, particleboard, plastics, and even aluminum. Now features Chrome Armor plating!

Infinity Cutting Tools has a saw blade in their inventory that a lot of folks don't understand. We call it the 10" Multi-Material 80-tooth saw blade. It was originally designed to cut materials like melamine (which is prone to chip-out) and non-ferrous metals like brass and aluminum. But this Tripple Chip Grind saw blade can do so much more.

The Grind

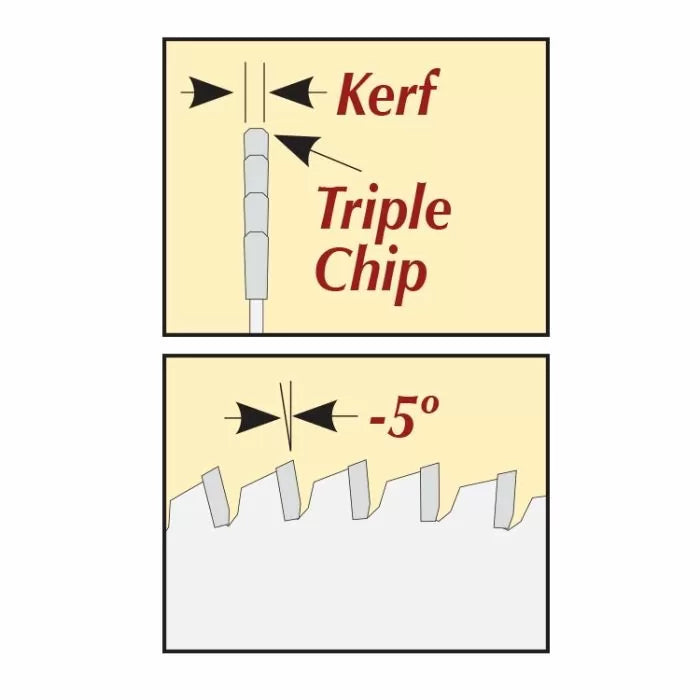

There are a couple of things that make this blade different than your run-of-the-mill combination, crosscut, or rip blade. First off, every tooth on the blade is a Triple-Chip Grind (TCG). This tooth configuration is designed so that each tooth takes a smaller bite without "grabbing" the material. It's common in industrial shops. The triple-chip grind also means you'll get less tear-out and chipping on the material as the blade exits the cut. Definitely important when working with melamine-coated sheet goods and cabinet-grade plywood with its paper-thin veneers.

Secondly, the teeth have a negative rake angle. This means that each tooth creates more of a shearing cut than blades with a positive rake angle. Combine this with having 80 teeth and you get a smoother cut.

The Tooth Count

The higher tooth count and negative rake angle make this blade behave a little differently than your typical, aggressive saw blade. Because there are many teeth, you can't feed the material into the blade as fast as you might be used to. You'll also want to keep the blade height pretty low (about half a tooth above the material) so that the teeth are cutting at a lower shear angle rather than the "chopping" action of a highly elevated blade.

I've cut all sorts of material with this blade including MDF, aluminum, and plywood. If you're looking for the ultimate edge, particularly with MDF, this blade really shines.

Not Just for the Tablesaw

Another great application for this blade is your miter saw or radial arm saw. The negative hook angle makes it ideal for these applications. You won't be disappointed in the quality of cross-grain cuts in hardwood and softwood using this blade.