10" Super General Combination Table Saw Blades

The Infinity Tools Super-General Table Saw Blades deliver precision cuts that are glass-smooth to the touch and feel. We've designed our 10” x 40 tooth Super-General table saw blade to perform supremely well in hardwoods, softwoods, veneered plywoods, melamine, and even plastics. Upgrade your table saw with our award-winning woodworking blades and enjoy the highest quality rips and crosscuts in your shop.

It used to be that there were two general classifications of table saw blades — rip and crosscut. In the days of high-speed steel blades (before carbide was widely available), these specialized blades were designed for either crosscutting (across the grain) or ripping (along the grain), but not both. To do the job right, you would switch out the blade depending on what type of cut you were going to make.

With the advent of carbide teeth on saw blades in combination with sophisticated, computer-controlled grinding equipment, it's becoming less common to have to switch out blades. Granted, if you're ripping a lot of hardwood, you're going to want a dedicated rip blade. But for the majority of table saw cuts in the home workshop, a combination blade is the one you'll use the most.

So, if you're shopping for a new saw blade, you need to consider it an investment in the quality of work you can produce in your shop. An inferior blade will cause more frustration with a poorer quality of cut and shorter lifespan.

The Super General combination table saw blade from Infinity Cutting Tools is one blade that excels at cutting just about any material it can sink its teeth into. It does a great job of ripping and crosscutting hardwood. And when it comes to getting clean cuts without chipout on sheet goods like veneered plywood and melamine, the Super General combination table saw blade is hard to beat.

Here are a few of the reasons why the Super General table saw blade should be the next thing you add to your shopping cart.

High-Quality Materials

All Super General saw blades start with the best in materials. The saw plate is made from the best quality, cold-rolled steel and is then precision-cut with a laser to minimize heat and distortion. The plate is then heat-treated and annealed in a computerized oven to relieve internal stresses for less warping during use.

Expansion Slots

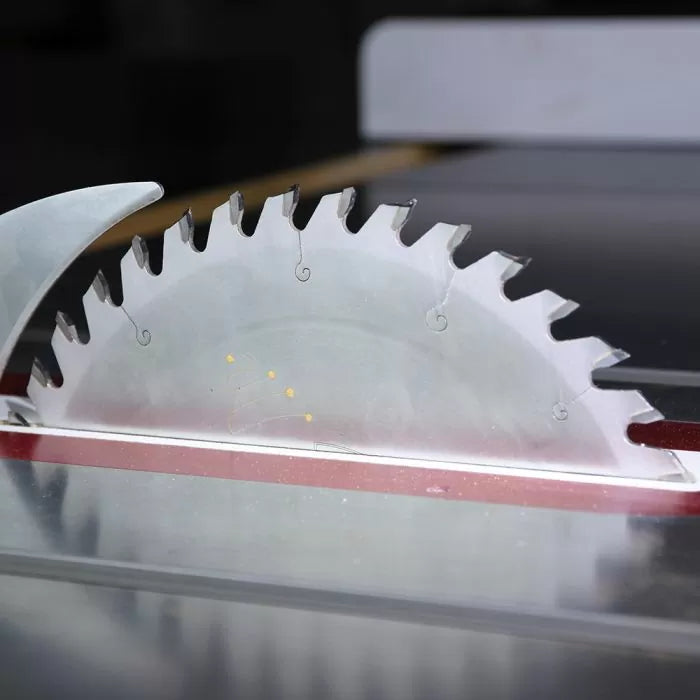

As you use a saw blade, friction from the cutting action heats up the blade, causing it to expand. Laser-cut expansion slots near the teeth allow the blade to run true in spite of this heat build-up.

Dampening Slots

Saw blades are noisy during use because of plate vibration. Strike most saw blades with a piece of metal and it will ring like a church bell. On the Super General saw blade, dampening slots are also cut with a laser and filled with a polymer to absorb vibration before it reaches the teeth of the blade. This makes the Super General one of the quietest saw blades you will ever use.

Tension

During the manufacturing process, the metal saw plate may have internal stresses that affect how true the blade runs as it heats up and expands. Tensioning the blade relieves these stresses and guarantees a flat saw plate. The steel plate for each Super General saw blade is tensioned at the factory. You'll notice a ring around the saw plate. This tension ring prevents the plate from deforming during use. What this means for you is a straight, clean cut every time.

Carbide Teeth

The most important part of the blade — the teeth — are where we focus a lot of attention. We start with thick, C4 micro-grain carbide. This carbide starts out sharper and remains sharp longer than those on other saw blades. This means you’ll get more life between sharpenings for a longer-lasting saw blade.

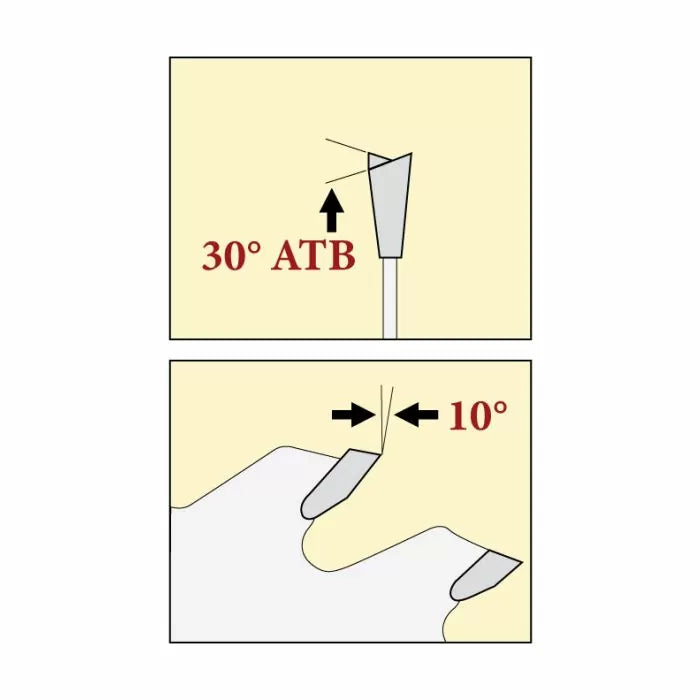

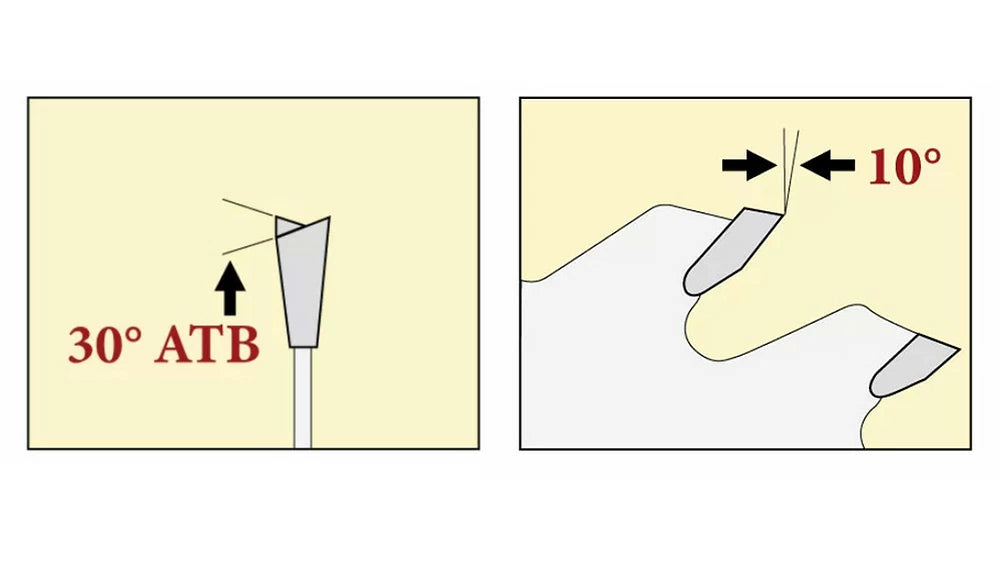

Tooth Grind

Advances in computerized grinding equipment have led to some pretty radical changes in tooth geometry over the last several years. The teeth on the Super General table saw blade feature a steep, 30° alternate top bevel. This creates an ultra-sharp cutting edge that is especially useful when cutting veneered plywood and MDF or melamine. The scoring action of the teeth minimizes chipout, resulting in a clean, smooth cut, regardless of the material.

The teeth also feature a double-side grind to increase the cut quality and the cutting efficiency of the Super General saw blade. I've used this blade to cut a lot of different materials and it leaves virtually no chipout where the blade exits the cut. The photo below shows what I mean. Even the thin birch veneer on the plywood and the melamine were cut cleanly.

NOTE: To get even better results when using the Super General saw blade on your table saw, use a zero-clearance insert. This helps support the material on either side of the blade on the exit side of the cut and greatly reduces tearout and chipping.

Blade Coating

The Chrome Armor coating keeps the Super General saw blade cooler by drawing heat away from the cutting edges. I know...it sounds like a marketing gimmick. But test results prove it. This coating also reduces friction and resists pitch build-up for a cleaner blade.

Laser-Cut Arbor Hole

In the photo above, you’ll notice that the arbor hole on the Super General features a small bump, or nipple, as we call it. This is proof that the arbor hole is cut with a laser instead of being stamped which can distort the saw plate. Cutting out the hole with a laser not only guarantees maximum accuracy with less runout, but it also hardens the edges of the arbor hole for longer life.

Using the Super General Table Saw Blade

There's one thing I want to point out about using the Super General table saw blade. When you set it up in your saw, adjust the height of the blade so only about one half of a tooth projects above the surface of the workpiece. I know there's a lot of debate about this, but we have found that doing this creates a low angle of attack of the tooth on the material. This gives the sharp point of the saw teeth more of an opportunity to score the material before cutting through it. How it works doesn't matter to me as much as the fact that it creates a super-smooth cut edge.

What Really Matters

All of this technology is great, but how does the blade really perform? I honestly have to say that this blade ranks right up there with one of the best-cutting blades I've used. I'll stack it up against any of the competitor's blades any day. What's most impressive to me is how well it cuts fragile material that's prone to tearout. I could barely find any chipout on plywood or melamine. To me, that's impressive.

If you're looking for a blade that you can keep in your table saw for 90% of your cuts, the Super General by Infinity Cutting Tools is it. And if you have a smaller table saw like a benchtop or contractor-style table saw, there's a thin-kerf version of the Super General that has all of the same great features. And if you own a SawStop table saw, the Super General works just fine on it, as well.

Purchasing a Super General saw blade is one decision you will never regret. I promise.